You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1/0 gauge 300 amp rating or not?

- Thread starter troye

- Start date

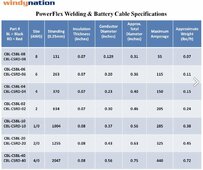

So this seems to support the claimWelding and battery cable from Windy Nation.

S Davis

Solar Enthusiast

- Joined

- Sep 25, 2021

- Messages

- 606

This is what the DLO cable I use is rated at. I would trust the 260 amp rating with this stuff.Free air 90C conductor, table shows 260A

Wire Size Chart for Conductors in Free Air

Wire Size Chart: Allowable Ampacities of Conductors in Free Air - 30Cwiresizecalculator.net

Can of course be higher if run hotter (silicone insulation) or forced air flow.

Or intermittent, especially very short time like a starter.

I think my system would put 900A through 4/0 (3 second 44kW surge) or 500A (23kW) "continuous" only until the batteries run down (which would take about 20 minutes, so I'm not worried.) If I had larger bank I'd use dual 4/0.

That's 4x SI 6048US with 405 Ah 48V SunXtender AGM.

scrubjaysnest

Solar Enthusiast

While testing a 3000w inverter with the 1/0 6 foot cable that came with it. At 270 amps after 5 minutes it was almost hot enough to burn you. Get 4/0 105C cable.

DPC

Solar Enthusiast

OK, according to the standard AWG copper resistance tables, 1/0 cable has 0.098 millliohms/foot (apologies to the metric audience) at 20 deg C.

Power = I^2 R, so each foot of cable would dissipate about 8.8W at 300A.

copper is inside the insulation, how hot would the cable get?

So your 5 ft of cable would dissipate 44W, and there are two cables (+ and -), so 88W total coming out of those 1/0 cables at 300A.

And a total voltage drop of about 0.3 V

That's better than I thought...

But i would still be inclined to use a larger a lot larger.

The duty cycle is something to consider too!

Your not going to pull 300 amps all the time.

44 watts is a considerable amount of heat for the cables to dissipate over such a short run

I used to work on a machine called a bolter that had a power cable Size #4 to supply the machine around 80 amps @ 600 volt.

The cable would get warm enough in my hand it was not pleasant to hold.. ( not that I ever thought holding cable pleasant or even while the power was on ).

This machine also had a duty cycle of about 50% and the length of cable was 150 feet.

At the machine the voltage would drop 30 volts.

All that sounds horrifying doesn't it?

Not really most machines would run just fine with a dip of 10% or less.

The cable insulation was rated to run as hot as 125c

So thats within specification.

Today however we run that same machine with a 2/0

Just because its easier to stock only that cable.

Last edited:

ricardocello

Watching and Learning

I think we have general consensus here that the OP should use at least 4/0.But i would still be inclined to use a larger a lot larger.

The original question was about the automotive ampacity tables being different and confusing.

I prefer hard math numbers like I posted above, or actual test experiences like @scrubjaysnest

I use double 1/0 cables with my Sol-Ark15k and at 250A+ continuous for an hour or so they only get mildly warm. I was using a single 1/0 with my 12k and that was limited to ~175A and I didn't see any major heat issue either. My run from inverter to busbar is very short though, ~2.5ft

hwy17

Anti-Solar Enthusiast

I think there is an equal argument towards fusing 2/0 at 200/225 amps and not utilizing a full 3000w on 12v. High amps are no fun, they make everything hot and expensive. I hope to never need a 4/0 wire in my life.I think we have general consensus here that the OP should use at least 4/0.

A 200 amp fuse will still allow short excursions into 300A for starting motors and stuff, which is also fine for the 2/0 wire too.

robbob2112

Doing more research, mosty harmless

While testing a 3000w inverter with the 1/0 6 foot cable that came with it. At 270 amps after 5 minutes it was almost hot enough to burn you. Get 4/0 105C cable.

Never trust the cables that come with inverters. Once in a while they are good pure copper 105c wire, but most of the time they are no-name CCA or undersized that they are marked, if they are marked at all.

So, would the 2 at 2/0 = 1 at 4/0, and therefore 2 fuses at 200a = 400a total?I think there is an equal argument towards fusing 2/0 at 200/225 amps and not utilizing a full 3000w on 12v. High amps are no fun, they make everything hot and expensive. I hope to never need a 4/0 wire in my life.

A 200 amp fuse will still allow short excursions into 300A for starting motors and stuff, which is also fine for the 2/0 wire too.

Edit - Blue sea has this chart: https://www.bluesea.com/support/art..._Fuse_Holder_For_Your_DC_Product_Installation

Last edited:

robbob2112

Doing more research, mosty harmless

So for 2/0 battery/welding wire the resistance is 0.0000983 ohms per foot - the previously stated value was for 1/0 of some other sort.

5ft round trip - so 2.5ft each - total resistance is 0.0004915 ohms.

P= i^2 * r = 250amps^2 * 0.0004915 = 30.7watts

Run two of the 2/0 and you drop resistance by half and cut the power loss in half. But now you have the additional resistance of the extra set of lugs. If your actual roundtrip distance is 10ft because they are 5ft apart and you need to double this value

In my opinion it is not really worth the cost to double up on the cables if you start with 2/0.

So assuming you keep with single 2/0 cables with a round trip of 5ft and fuse just the positive at 200 amps you should be good to go. If you want the full 3000w fuse at 250amps and you will peak at 234amps.

Either way it wouldn't even warm the cable up perceptibly because you won't be pulling 250amps but for motor startups and in all likelyhood you will pull a lot less and the distance is so short the cables can actually handle a lot more. The ampacity charts are generally for 25ft or more.

note - this is just a restatement of what hyw17 said with some added details.

5ft round trip - so 2.5ft each - total resistance is 0.0004915 ohms.

P= i^2 * r = 250amps^2 * 0.0004915 = 30.7watts

Run two of the 2/0 and you drop resistance by half and cut the power loss in half. But now you have the additional resistance of the extra set of lugs. If your actual roundtrip distance is 10ft because they are 5ft apart and you need to double this value

In my opinion it is not really worth the cost to double up on the cables if you start with 2/0.

So assuming you keep with single 2/0 cables with a round trip of 5ft and fuse just the positive at 200 amps you should be good to go. If you want the full 3000w fuse at 250amps and you will peak at 234amps.

Either way it wouldn't even warm the cable up perceptibly because you won't be pulling 250amps but for motor startups and in all likelyhood you will pull a lot less and the distance is so short the cables can actually handle a lot more. The ampacity charts are generally for 25ft or more.

note - this is just a restatement of what hyw17 said with some added details.

DPC

Solar Enthusiast

I think we have general consensus here that the OP should use at least 4/0.

The original question was about the automotive ampacity tables being different and confusing.

I prefer hard math numbers like I posted above, or actual test experiences like @scrubjaysnest

It might be better to use actual electrical code tables.

I wont even pretend to know USA codes but I know they will be close to Canadian codes.

We should try to keep our voltage drop around 3% - maybe 5% max.

But 5% at 120 volt is only about 6 volts, but 6 volts on a 12 volt system thats intolerable....

There are also de-rating factors to consider for the cable based on types of cable and application even duty cycle,,,

Since I an not an American, do not live in the USA, and do not use the NEC, or have even ever seen it I don't even pretend to know what the rules are for what we call extra low voltage wiring up here...

But I am pretty sure your Insurance company will expect you to follow these rules or they will decline your claim in case of a fire.

What I do for a living is a little different from homes.

My work is governed by codes related to heavy industry, high voltage and not general purpose wiring for homes.

I except no liability and claim no expertise in USA building codes and suggest you not listen to anything I say but instead refer all questions to Qualified electrical safety authority and the NEC and building regulation in your local municipality...

But that all said no one ever got in trouble for running a bigger wire.

Just know when to quit, if your pulling 500 your went to far lol

( if you go past the Dolphin people you went too far... )

Similar threads

- Replies

- 16

- Views

- 2K