offgridfarmgineer

New Member

- Joined

- Jan 22, 2022

- Messages

- 25

Hey all, first post there. I have been off-grid for over a year with our Mitchcraft tiny house and starting a farm (on the side while working full time jobs). We are just north of Santa Fe, NM and very common to be 10F or lower in winter and up to 100F in summer. We have 2.9 kW REC Alpha panel system, all the Schneider XANBUS connected stuff and 330 Ah of CR330 FLAs. Batteries and BOS are in one of our shipping containers in an insulated box. Lost a good amount of capacity (probably due to some over discharge and high temps in summer) and tired of worrying about whether we can run a toaster in the mornings or needing to turn on our propane generator. Just ordered 4 EG4-LLs just to really boost our capacity (we often aren't using all our panel output, just need more storage) and look forward to not needing them to get to 100% charge and be able to bank capacity for those times when we want a lot of power at night.

I didn't want to buy the Signature Solar racks so looking at other options. The EG4s are just under 3.5 U but I see they are often shown mounted w gaps. Is it possible to mount them directly above each other? Reason I'm asking is 4x3.5 is 14U and 15U racks are common, but do I actually need 16U or higher?

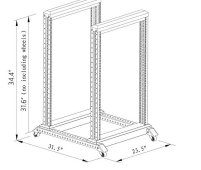

I'm looking at buying the rack below off amazon, 15U and 24" deep. It comes with 2 sets of rails and I was going to buy slotted metal angle for the other two pairs since people charge insane amounts for simple thin rails. I was going to make my own busbars in plastic finger tray ("panduit") and see that the neatest solution is to mount the EG4s on the inside of the vertical rails (this rack has two sets of square mounting holes per post, plus perpendicular holes for surface mounting the rails) so there is room in front of them for the busbars. This is unlike normal mounting on the outside vertical rail holes. I plan to surround the rack with 2" foam board to keep it warm in winter and cooler in summer (will add intake and exhaust to air external to the shipping container for the summer.

Comments?

I think I understand that the EG4-LLs do NOT have a start-up issue with my SW 4048, unlike the EG4 Lifepower, is that correct? Any tips?

Since they unfortunately won't communicate with my Schneider connected devices, for communication with a laptop occasionally I just connect all the battery comms and then connect to one from RS485 to my usb port to check in on things?

@Will Prowse youtube is great and so is this forum, I never used any of this for my initial install I did myself and wish I understood LiFEPO4 better a years ago when I thought my only choice was a Discover battery. I purchased everything from unbound solar and they were great, but I underestimated the FLA issues.

I didn't want to buy the Signature Solar racks so looking at other options. The EG4s are just under 3.5 U but I see they are often shown mounted w gaps. Is it possible to mount them directly above each other? Reason I'm asking is 4x3.5 is 14U and 15U racks are common, but do I actually need 16U or higher?

I'm looking at buying the rack below off amazon, 15U and 24" deep. It comes with 2 sets of rails and I was going to buy slotted metal angle for the other two pairs since people charge insane amounts for simple thin rails. I was going to make my own busbars in plastic finger tray ("panduit") and see that the neatest solution is to mount the EG4s on the inside of the vertical rails (this rack has two sets of square mounting holes per post, plus perpendicular holes for surface mounting the rails) so there is room in front of them for the busbars. This is unlike normal mounting on the outside vertical rail holes. I plan to surround the rack with 2" foam board to keep it warm in winter and cooler in summer (will add intake and exhaust to air external to the shipping container for the summer.

Comments?

I think I understand that the EG4-LLs do NOT have a start-up issue with my SW 4048, unlike the EG4 Lifepower, is that correct? Any tips?

Since they unfortunately won't communicate with my Schneider connected devices, for communication with a laptop occasionally I just connect all the battery comms and then connect to one from RS485 to my usb port to check in on things?

@Will Prowse youtube is great and so is this forum, I never used any of this for my initial install I did myself and wish I understood LiFEPO4 better a years ago when I thought my only choice was a Discover battery. I purchased everything from unbound solar and they were great, but I underestimated the FLA issues.

Last edited: