Yeah the weak point is probably the trailer roof rails to the walls. But those are welded, and are many. I think we should see a broken weld before the whole thing comes of.

I bolted M8 through the roof trusses and put locking nuts underneath - so impossible to pull out. I think you drilled and put screws from above ?

Your panels are resting directly on the Unistrut? I saw some people adding a small spacer there in between?

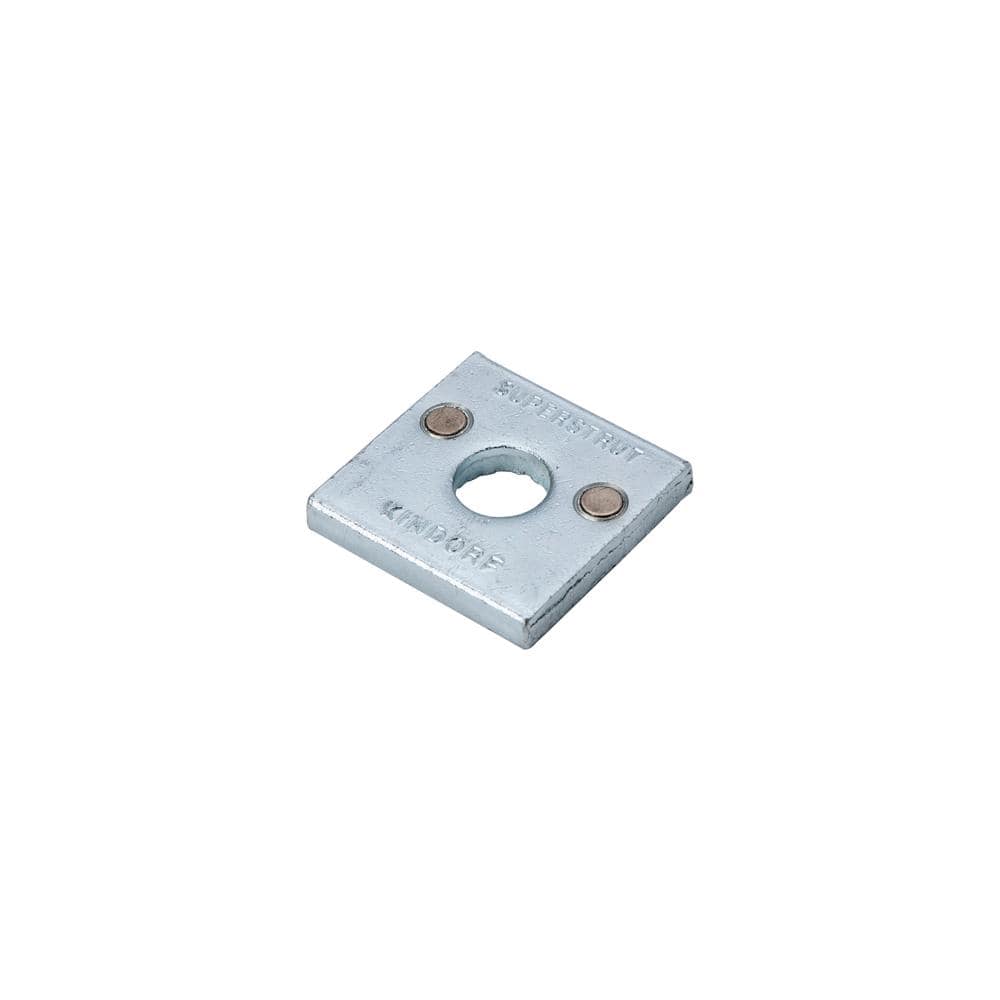

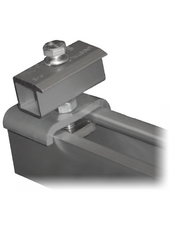

I used those:

https://a.co/d/7oJXDVN to space my strut from the trailer roof. So water can drain underneath.

diysolarforum.com