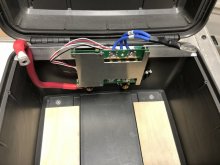

TLDR - My conclusion - the Seahorse SE540 is an excellent enclosure for a 4S 280ah sized LiFePO4 prismatic cell build with the JBD BMS. Only concerns would be the vertical space is limited (or very efficiently used) if you need to add padding below or above - 20mm studs are probably too long - I used 16mm. Also, with the handle on the side of the case, and with how heavy it is, it's a bit awkard to pick up and move around. Also, without having lived with it for a while, I have no idea if there will be any sort of cooling/ventilation issues, but for my application I don't plan to push the battery or BMS very hard.

Other conclusions - I ditched the breaker from the initial design and just added the low voltage (logic) switch to turn the BMS on and off (or Bluetooth/iPhone app). I'll have a main disconnect and breaker in the trailer instead.

So... Why this battery and this particular enclosure?

I'm building a Teardrop Trailer and wanted something that would let me boondock (camp off-grid) for 3-4 (5?) days without the need to recharge (solar can come later if needed). The 280ah should be plenty for my low power needs and will hopefully give me the duration I'm looking for. With the weight of the galley (cooler/stove/etc) at the back of the trailer, I wanted to push the battery weight onto the front (tongue) of the trailer. This exposes the battery to the elements so, I needed something that was durable and well sealed. This Seahorse case looked like a clean and secure way to accomplish my goals.

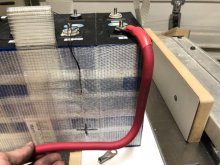

Here's a few images of my planned installation and how I modified the case. There are molded features in the bottom for you to screw into from inside, but I just drilled through, added a countersink and will use this to bolt directly to the trailer. Downside is that these bolts are basically permanently captured (unless I disassemble the battery) - I have some threaded bumpers on order from McMaster to use when the battery isn't on the trailer.

More images of box modifications and the internals coming soon...

-uberpixel