Interestingly, I just noticed that REC released a new firmware (2.8.1) that comes in to flavours. Both versions will disconnect the charge contactor in case of an over voltage condition, however the behaviour differs when dealing with an under voltage situation. The -1 version will disconnect both charge and discharge contactors in case of an under voltage alarm. The -2 version will only disconnect the discharge contactor.E-13 does not require UL listing. Victron would be an excellent choice if you want to be ABYC compliant. If you stay with the Victron ecosystem and add a wakespeed regulator controlled by the Victron BMS you will have exactly what ABYC intends or recommends people do. You probably couldn't do any better-which is why they demand a high price.

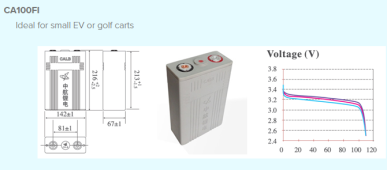

Another excellent choice would be DIY with Winson/CALB/Sinopoly cells, and a REC BMS controlling a wakespeed.

Down on the list are DIY with DALY or Overkill BMS, which meet ABYC requirements, but not recommendations. Decent communication via an app, ability to monitor or test cells with a voltmeter, but no control of charge sources.

Last choice would be the cheaper drop-ins, where there is little or no way of knowing what is going on inside, and no communication with charge sources.

In my case, since I’m using a blue sea relay with manual override, I’m figuring I’ll stick with the -1 version.

2.8.1 also apparently improves compatibility with the WS500, so I’ll probably install it and see what happens.