You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

bus bar or 4/0 welding cable for this??

- Thread starter pvdude

- Start date

Boondock Saint

Solar Enthusiast

- Joined

- Apr 8, 2021

- Messages

- 661

These are 6v yes? Are you connecting them in series or parallel? Or how many of which config?

Diysolar123

Solar Addict

- Joined

- Feb 28, 2021

- Messages

- 675

so the first thing to consider is...what will be your current load?

once you know what the load is, well, that will let you know how much copper you need.

Bus bar or cable, its the cross-sectional area of the copper that matters when figuring out ampacity.

Things to think about:

welding cable is a commodity item which means easy to get and replace

bus bars are the "highest capacity" in a given area as its just solid copper. (the more wire strands in a cable results in a reduction in current capacity)

I have not seen a AWG/wire core table with nearly as many cores as flex welding has (>1000 strands); but you can look at this table which shows some values for multicore: https://www.engineeringtoolbox.com/wire-gauges-d_419.html

not sure about silver plated copper in a lead acid environment

once you know what the load is, well, that will let you know how much copper you need.

Bus bar or cable, its the cross-sectional area of the copper that matters when figuring out ampacity.

Things to think about:

welding cable is a commodity item which means easy to get and replace

bus bars are the "highest capacity" in a given area as its just solid copper. (the more wire strands in a cable results in a reduction in current capacity)

I have not seen a AWG/wire core table with nearly as many cores as flex welding has (>1000 strands); but you can look at this table which shows some values for multicore: https://www.engineeringtoolbox.com/wire-gauges-d_419.html

not sure about silver plated copper in a lead acid environment

Cables means the lug to cable interface will eventually deteriorate causing high resistance and/or lug separation. You can mitigate this with really good cold weld crimps and sealing the crimp well with glue-backed heat shrink but it is only delaying the inevitable.

I prefer bus bars as they are more reliable and for your application it looks like the terminals would work well with bus bars.

I prefer bus bars as they are more reliable and for your application it looks like the terminals would work well with bus bars.

I’m not sure how to determine the maximum current coming from the batteries.

- the inverter is rated at 6800 watts continuous. So the ac amps is about 28.

- the inverter will also do 8000 watts for 30 minutes (33 ac A), and

12,000 watts for 30 seconds (50 ac A)

I have no idea how to determine the DC amps from the batteries, based on the AC amps load.

- the breaker for the “+” battery connection is 250 dc amps.

There is a software setting called “Maximum discharge current” , default is 150A, but the setting can be configured for up to 500A

I will be installing a battery monitor that includes a shunt, so eventually can obtain an accurate measurement of the current.

- the inverter is rated at 6800 watts continuous. So the ac amps is about 28.

- the inverter will also do 8000 watts for 30 minutes (33 ac A), and

12,000 watts for 30 seconds (50 ac A)

I have no idea how to determine the DC amps from the batteries, based on the AC amps load.

- the breaker for the “+” battery connection is 250 dc amps.

There is a software setting called “Maximum discharge current” , default is 150A, but the setting can be configured for up to 500A

I will be installing a battery monitor that includes a shunt, so eventually can obtain an accurate measurement of the current.

Boondock Saint

Solar Enthusiast

- Joined

- Apr 8, 2021

- Messages

- 661

I didn't ask about the gauge because he stated what he has. This or that. But if it's 48v rather than 12v, the cabling or bus bars would be a lessor requirement.

pvdude - is this a house BU plan? In other words, if you don't KNOW what your potential load is on the inverter, then you need to calculate the draw from the individual and collective appliances it will feed. What are the largest consumers you would be running at the same time? If you know what then work backwards for the inverter load and draw from the batts.

Just because you HAVE an 6800w inverter doesn't mean you'll use all that at the same time or ever exceed it.

pvdude - is this a house BU plan? In other words, if you don't KNOW what your potential load is on the inverter, then you need to calculate the draw from the individual and collective appliances it will feed. What are the largest consumers you would be running at the same time? If you know what then work backwards for the inverter load and draw from the batts.

Just because you HAVE an 6800w inverter doesn't mean you'll use all that at the same time or ever exceed it.

The system is basically going to run the well pump and shop AC.

In an emergency, we can use it to run the house, if we are very careful about loads.

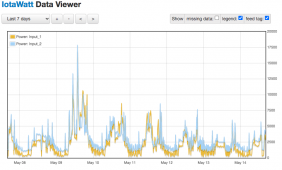

You can see from the data that over the last 7 days, only one day exceeds the system capacity.

(Dryer, washer, water heater, pool pumps all going at once)

I am going to go w/ bus bar for the connections, as I have the material, and no other use for it.

In an emergency, we can use it to run the house, if we are very careful about loads.

You can see from the data that over the last 7 days, only one day exceeds the system capacity.

(Dryer, washer, water heater, pool pumps all going at once)

I am going to go w/ bus bar for the connections, as I have the material, and no other use for it.

The New JC777

New Member

- Joined

- Sep 17, 2020

- Messages

- 152

I agree.I am going to go w/ bus bar for the connections, as I have the material, and no other use for it.

You will want to have clean bright surfaces at the contact patch of the bar and the terminal.

Use a conductive grease between the contact patch to help keep out the corrosive gasses.

Use water miser caps to reduce water consumption. I think they also recombine the gasses.

Don't over torque the fasteners. The lead will compress (Creep) over time causing bad connections.

After a few hours of making copper chips, now ready to make some sparks!

View attachment 49206

View attachment 49207

Thats the big-boy metal saw!

The New JC777

New Member

- Joined

- Sep 17, 2020

- Messages

- 152

My eyes aint as good as the used to be. It looks like you have 2 small ga, wires with fuses connected to terminals other than 48 volts. What is their purpose?

I'm a tad jealous of whatever badass tool that is you're using to cut copper. What is it called?After a few hours of making copper chips, now ready to make some sparks!

View attachment 49206

View attachment 49207

Boondock Saint

Solar Enthusiast

- Joined

- Apr 8, 2021

- Messages

- 661

I called it the @SS-RIP 5400, part of the Binford 5000 series.

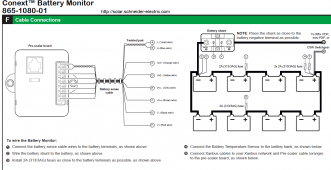

The tiny wires connected at various places on the batteries are from the battery monitor.

No idea what a “Pre-scaler” is, I just connected everything like the instructions said.

The metalworking thing is a 1962 Bridgeport milling machine, a local machine shop wanted to get rid of it cheap, very happy to oblige, it still works great.

No idea what a “Pre-scaler” is, I just connected everything like the instructions said.

The metalworking thing is a 1962 Bridgeport milling machine, a local machine shop wanted to get rid of it cheap, very happy to oblige, it still works great.

Similar threads

- Replies

- 15

- Views

- 676

- Replies

- 3

- Views

- 378

- Replies

- 7

- Views

- 348