You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Capacity test

- Thread starter Robbiee

- Start date

chrisski

Solar Boondocker

- Joined

- Aug 14, 2020

- Messages

- 5,257

For the four batteries I have, I have only capacity tested the two lithium 25 ah batteries, not the two lithium 280 ah batteries. In part because of what you mention about harming the battery. The other part is just how much time it takes.

The two I did not capacity test were grade A from a vendor with results of a capacity test and internal resistance sent to me prior to the shipment. If these are Grade B cells, capacity testing helps. I two batteries I capacity tested jad cellls from two different vendors.

I had another four lead acid I did not even consider capacity testing.

The two I did not capacity test were grade A from a vendor with results of a capacity test and internal resistance sent to me prior to the shipment. If these are Grade B cells, capacity testing helps. I two batteries I capacity tested jad cellls from two different vendors.

I had another four lead acid I did not even consider capacity testing.

a single proper 100-0 cycle or occasional full cycles shouldn't have any meaningful negative impact to the best of my understanding.I see on youtube everyone seems to do a %100 discharge to check battery capacity. Does this not harm a new battery to drain it like that?

Cells are normally rated/tested by the factory at 0-100 cycling. When in doubt read the cell datasheet.

The tests you see are discharging until the internal Battery Management System (BMS) does a low voltage cutout. The individual ceslls inside the battery are not being 100% discharged - only down to the cutoff voltage set in the BMS.I see on youtube everyone seems to do a %100 discharge to check battery capacity. Does this not harm a new battery to drain it like that?

robby

Photon Vampire

- Joined

- May 1, 2021

- Messages

- 4,156

Very true when it comes to packs with the BMS installed but some people are doing it with individual cells.The tests you see are discharging until the internal Battery Management System (BMS) does a low voltage cutout. The individual ceslls inside the battery are not being 100% discharged - only down to the cutoff voltage set in the BMS.

It's probably best to have a discharge system that cuts off at a certain voltage when doing this.

I believe the cheap little testers with the fans/heatsinks many people use for capacity testing single cells do have a configurable low voltage shutdown so they can be set to automatically disconnect. Personally I would want to verify it works correctly and is accurate before trusting it, but then this is a good idea with a BMS as well.Very true when it comes to packs with the BMS installed but some people are doing it with individual cells.

It's probably best to have a discharge system that cuts off at a certain voltage when doing this.

meetyg

Solar Addict

- Joined

- Jun 4, 2021

- Messages

- 1,103

I use a DL24 capacity tester. It's a nice little gadget, but limited to ~150w.

I do all my capacity tests for Lifepo4 cells setting low voltage cutoff at 2.6v.

In practice, the cells don't really reach that voltage while testing, because of the voltage drop with the load on. So while the tester sees 2.6v under load, the cells are actually around 2.9v. I use the tester with a 4-wire configuration, in order to read voltage correctly, but still there is a voltage drop when the Lifepo4 cells get close to full discharge.

So no harm done to the cells (I think...) and I have gotten pretty accurate capacity results with this method.

I do all my capacity tests for Lifepo4 cells setting low voltage cutoff at 2.6v.

In practice, the cells don't really reach that voltage while testing, because of the voltage drop with the load on. So while the tester sees 2.6v under load, the cells are actually around 2.9v. I use the tester with a 4-wire configuration, in order to read voltage correctly, but still there is a voltage drop when the Lifepo4 cells get close to full discharge.

So no harm done to the cells (I think...) and I have gotten pretty accurate capacity results with this method.

chrisski

Solar Boondocker

- Joined

- Aug 14, 2020

- Messages

- 5,257

Yes, but you’d need to know

I’m not a fan of capacity testing lead acid batteries because the lower state of charge/great depth of discharge shortens the number of charge cycles.

Especially for a discharge to 0%. Also, if you choose 50% for a test, how do you really know how much is left. Finally, will the results change in anyway how you assemble your batteries.

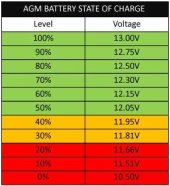

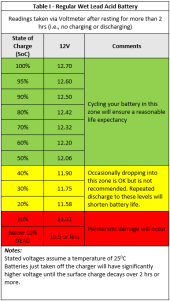

what the voltages were for the state you want.Would DL24 work to test capacity for AGM batteries?

I’m not a fan of capacity testing lead acid batteries because the lower state of charge/great depth of discharge shortens the number of charge cycles.

Especially for a discharge to 0%. Also, if you choose 50% for a test, how do you really know how much is left. Finally, will the results change in anyway how you assemble your batteries.

CroModder

New Member

- Joined

- Jun 18, 2022

- Messages

- 5

I apologise in advance for my lack of knowledge. What I would like is to test in what condition my batteries are.

I have two Poweroad PR100-12 (12V, 100Ah) batteries connected into series. And since that is not enough to power up the fridge throughout the night so I want to invest and purchase another 2 batteries and connect them in parallel.

But a guy in my local solar shop said that I should check in what condition my current batteries are, and if they have low capacity that this could potentially damage new batteries.

I was hoping that having this one greater DoD is not going to have such a strong impact on charge cycles. If I set up cut out voltage to 11.51V (10% level, so the battery doesn't really reach the 0%). Then I wouldn't know the exact battery capacity but I would still know that my batteries are not worn out that much. Or I am missing something?

I found one DL24 on aliexpress but it says it's meant for Lithium batteries, so I wouldn't experiment with that unless someone knowledgeable says it will work for SLA batteries too.

I have two Poweroad PR100-12 (12V, 100Ah) batteries connected into series. And since that is not enough to power up the fridge throughout the night so I want to invest and purchase another 2 batteries and connect them in parallel.

But a guy in my local solar shop said that I should check in what condition my current batteries are, and if they have low capacity that this could potentially damage new batteries.

I was hoping that having this one greater DoD is not going to have such a strong impact on charge cycles. If I set up cut out voltage to 11.51V (10% level, so the battery doesn't really reach the 0%). Then I wouldn't know the exact battery capacity but I would still know that my batteries are not worn out that much. Or I am missing something?

I found one DL24 on aliexpress but it says it's meant for Lithium batteries, so I wouldn't experiment with that unless someone knowledgeable says it will work for SLA batteries too.

chrisski

Solar Boondocker

- Joined

- Aug 14, 2020

- Messages

- 5,257

CroModder

New Member

- Joined

- Jun 18, 2022

- Messages

- 5

@meetyg - I just stumbled upon this video from Will Prowse about Battery capacity test and the first pinned comment says that this cutoff voltage/low voltage protection doesn't work. Can you please share info if it works in your case? And if it is working, what version of DL24 are you using?The DL24 is programmable, so I don't see why you couldn't use it with SLA batteries.

You just need to set proper cutoff voltage for your batteries, and probably run it in constant current mode.

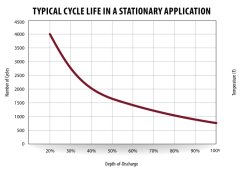

Thanks for the chart @chrisski. Last night I did some reading about DoD and battery cycle life, and in this article read the following:Going to 50% gets 1500 cycles, but going to 10% gets you 100 cycles

Here is the image that this statement was referring to:The yellow region past 50% is not overly damaging to your batteries, but consistent cycling to this level will shorten their lifespan. Clearly, the red region past 80% should be avoided unless absolutely necessary, say in case of emergency.

Although this is a chart for wet/flooded batteries, does this also translates for SLA batteries? If so, then it shouldn't be a problem to discharge it once to let's say 20%?

How does one add more batteries to the existing ones, if capacity testing is not worth it? Or the statement that low capacity batteries would damage the new ones isn't true?To me I read between the lines saying capacity testing a lead acid battery is not worth it.

meetyg

Solar Addict

- Joined

- Jun 4, 2021

- Messages

- 1,103

I'm using the one with the color display (DL24P)@meetyg - I just stumbled upon this video from Will Prowse about Battery capacity test and the first pinned comment says that this cutoff voltage/low voltage protection doesn't work. Can you please share info if it works in your case? And if it is working, what version of DL24 are you using?

Thanks for the chart @chrisski. Last night I did some reading about DoD and battery cycle life, and in this article read the following:

Here is the image that this statement was referring to:

View attachment 100559

Although this is a chart for wet/flooded batteries, does this also translates for SLA batteries? If so, then it shouldn't be a problem to discharge it once to let's say 20%?

How does one add more batteries to the existing ones, if capacity testing is not worth it? Or the statement that low capacity batteries would damage the new ones isn't true?

This model has a 4 wire connection: Pos and Neg for capacity testing, and another pair (for thinner wire) for voltage sensing.

Using the 4 wire connection I haven't had any problems with voltage cutoff.

I think the model Will has is an older model, which from other reviews seems to be more cumbersome to configure and less accurate than the the color LCD model.

chrisski

Solar Boondocker

- Joined

- Aug 14, 2020

- Messages

- 5,257

I can’t say. I would only say that if it were me, the only time I’d do the capacity test would be if I could replace the entire bank if things went wrong.Although this is a chart for wet/flooded batteries, does this also translates for SLA batteries? If so, then it shouldn't be a problem to discharge it once to let's say 20%?

For my lead acid Trojan batteries they were not cheap, four were delivered new to my house on a tractor trailer a month after ordered. I did not want to chance shortening a span of the battery life to get data which I would not use to rearrage my battery setup by doing a capacity test. The Trojans should last 10 years. I’m not sure how much capacity testing once would have got data.

I’ve done this two years and instead of adding additional capcity with lead acid, I went to lithiums because what I researched said the older batteries drug down the newer ones. With an RV build, I also needed less weight.How does one add more batteries to the existing ones, if capacity testing is not worth it? Or the statement that low capacity batteries would damage the new ones isn't true?

I’ve seen explanations with internal resistance for batteries newer being lower and older being higher that show how much extra the new batteries work, but I don’t know how these people measured the internal resistance.

CroModder

New Member

- Joined

- Jun 18, 2022

- Messages

- 5

Regarding internal resistance, according to this article , this seems like a false notion:

Anyway, thank you for all the inputs. I won't be throwing money on DL24 for this since I probably won't get the desired data and could potentially just shorten AGM battery life span. So, I will maybe try replacing my PWM SCC with MPPT to get some extra juice into battery before the night if that will help, but won't go off topic here since this thread is about battery capacity...

There is a notion that internal resistance is related to capacity, but this is false. The resistance of modern lead acid and lithium-ion batteries stays flat through most of the service life.

Anyway, thank you for all the inputs. I won't be throwing money on DL24 for this since I probably won't get the desired data and could potentially just shorten AGM battery life span. So, I will maybe try replacing my PWM SCC with MPPT to get some extra juice into battery before the night if that will help, but won't go off topic here since this thread is about battery capacity...

Similar threads

- Replies

- 6

- Views

- 384