Mario,

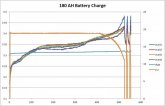

Thanks for the screenshots! Impressive job!

Are you open to sharing a little context on how you chose 0 seconds for your cut-off delay time? Is there a scenario where if you set this for a few seconds you'd have some risk of catastrophe?

I realize our systems are different, mine is 12V, 280Ah in an RV. I had thought a bit of delay, say up to 15 seconds may allow for some motor in-rush or other high-draw startup.

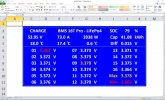

Also, what is the max delta V that you've experienced? I have very few cycles and under high load (150A) I saw 35mV or 40mV. So I moved my max to 75mV, but maybe 100mV is better. I don't want the battery to disconnect unnecessarily.

Thank you,

Doug