Well, if the cells have no possibility of chafing or otherwise allowing the wrap to wear through two layers, yes. I would add a more durable insulation in a mobile setup. I also said that I will probably add the baggies to mine even though it is a static system (and the box will weigh over 300 pounds). It is pretty simple to do, so I probably will do it even though 660 pounds of compression on the cells is likely to keep them from moving at all.Two layers of shrink wrap keeping a battery cell from shorting out? You really think that is not a potential catastrophic issue?

Rather than sarcastically quiz me about it, why don't you answer my question? How much insulation is enough? You didn't suggest a thickness or a type. I note that the potential from cell to cell is less than four volts, so it isn't like it is ready to arc through from cell to cell without provocation. Given that the dielectric strength of plastics starts at about 15 volts per micron, it doesn't take much plastic at all to keep your catastrophe from happening.

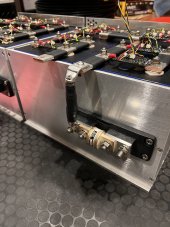

If you are going to add insulation, consider the bottom of the cells also if you have a conductive floor in your box. The bottoms of the cells only have one layer of shrink wrap protecting them.