AlaskanNoob

Solar Enthusiast

- Joined

- Feb 20, 2021

- Messages

- 906

Fire isn't a worry as much because this particular install is keeping the batteries basically underground in a structure that is separate from the house.

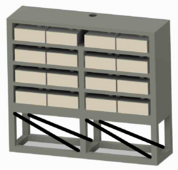

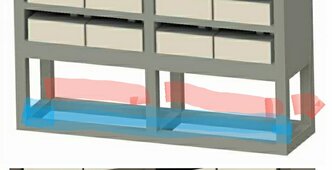

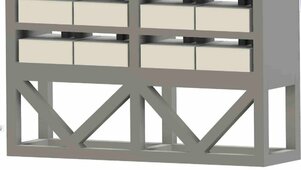

Old concrete form boards work good but I'm a fan of old pallet racking or a new smaller pallet rack like Costco sells.

Yeah, but if caught fire it would almost certainly burn down the solar shed and everything in it and depending on the wind and season it might start a forest fire that would burn down our cabin and be much worse.

Again, I'm banking on these systems working properly as advertised given I don't think there is a cost effective way to protect from fire. The temps I've seen are so hot that I don't think there is much that can be done if they go blazing.

What are these pallet boards? Are they better than those cement mesh boards?

Last edited: