AlaskanNoob

Solar Enthusiast

- Joined

- Feb 20, 2021

- Messages

- 906

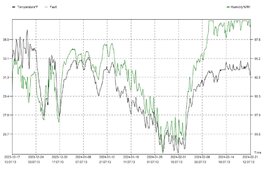

So the 8 x Pylontech US5000 we currently have stored in our uninsulated solar shed are not braving Alaska winters well. I wasn't sure how much they would heat up with charging and discharging, turns out not much. So when they get below freezing, it throws a wrench into the system. Fortunately, I built the shed on top of a root cellar (made from a buried 12' diameter culvert) so this summer I'm going to move the batteries down there which should keep them above freezing even when it gets down to -5F or so.

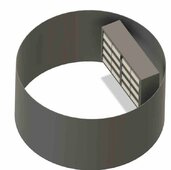

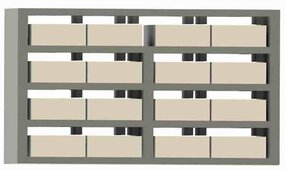

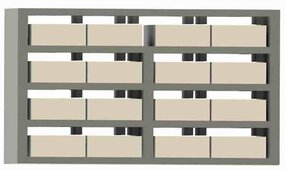

But, just in case, I'm going to build an insulated cabinet for them. I have no meaningful woodworking experience, but I want to get this right and I'm going to build it for 16 batteries since we're planning on doubling them.

Not shown is a plywood front and back. Front will open up in some way for access. Both front and back plywood will share four 12V heating pads. Also not shown is a base I need to construct for this thing to sit on, that will keep it about 2 feet off the concrete floor of the cellar and will keep the batteries as close to the root cellar ceiling (floor of the solar shed) to minimize wire lengths up to the bus bar in the solar shed.

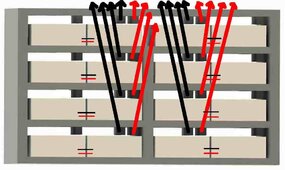

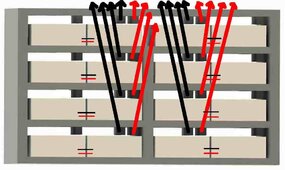

Shown on the top of each battery (screwed into the shelf above it) is a t-fuse holder. And the center 8 batteries will also have a "bridge" where I'll take the small factory power cables and connect them to thicker cables (probably 4/0) so the extra battery length doesn't provide too much resistance.

My three questions for the generous in the group:

A) should I put a vapor barrier inside the cabinet since the air will be humid, and the battery compartment air will be much warmer than the outside air? Or should I put the vapor barrier on the outside of the cabinet? For homes, the vapor barrier goes inside the home, but I want to ensure any condensation is outside the battery cabinet.

B) each shelf will hold 352 pounds of batteries -- should I construct this shelf differently for that load? I did a sag calculator and with my planned 2" thick shelves, there is no sag to speak of. Planning on 3" side walls, likely with a metal plate on the outside to connect them together, along with screws through the wood on the sides.

C) should I insulate with XPS foam on the outside, or spray closed cell polyurethane instead (which would also serve as a vapor barrier)?

Many thanks for any words of wisdom!

Also not shown are the holes for the cables from the center two columns going up to the bus bar. The outer columns will just be connected to the interior columns with the factory cables.

But, just in case, I'm going to build an insulated cabinet for them. I have no meaningful woodworking experience, but I want to get this right and I'm going to build it for 16 batteries since we're planning on doubling them.

Not shown is a plywood front and back. Front will open up in some way for access. Both front and back plywood will share four 12V heating pads. Also not shown is a base I need to construct for this thing to sit on, that will keep it about 2 feet off the concrete floor of the cellar and will keep the batteries as close to the root cellar ceiling (floor of the solar shed) to minimize wire lengths up to the bus bar in the solar shed.

Shown on the top of each battery (screwed into the shelf above it) is a t-fuse holder. And the center 8 batteries will also have a "bridge" where I'll take the small factory power cables and connect them to thicker cables (probably 4/0) so the extra battery length doesn't provide too much resistance.

My three questions for the generous in the group:

A) should I put a vapor barrier inside the cabinet since the air will be humid, and the battery compartment air will be much warmer than the outside air? Or should I put the vapor barrier on the outside of the cabinet? For homes, the vapor barrier goes inside the home, but I want to ensure any condensation is outside the battery cabinet.

B) each shelf will hold 352 pounds of batteries -- should I construct this shelf differently for that load? I did a sag calculator and with my planned 2" thick shelves, there is no sag to speak of. Planning on 3" side walls, likely with a metal plate on the outside to connect them together, along with screws through the wood on the sides.

C) should I insulate with XPS foam on the outside, or spray closed cell polyurethane instead (which would also serve as a vapor barrier)?

Many thanks for any words of wisdom!

Also not shown are the holes for the cables from the center two columns going up to the bus bar. The outer columns will just be connected to the interior columns with the factory cables.

Attachments

Last edited: