Cheapest 10k ohm, 0.05% matching network I found was $3.70 each, $2.44 for 100.

What can you find?

Order today, ships today. MPM2002AT1 – 10k Ohm ±0.1% 100mW Power Per Element Voltage Divider 2 Resistor Network/Array ±25ppm/°C TO-236-3, SC-59, SOT-23-3 from Vishay Dale Thin Film. Pricing and Availability on millions of electronic components from Digi-Key Electronics.

www.digikey.com

I've used 0.1% parts, tried to count on tracking of values. Mostly 10 ppm to 25 ppm/degree.

Checking DigiKey for 0603 sizes, 10k ohm as an example,

cheapest 0.1% I find is $0.23 each, $0.075 in strip of 100. That's 50 ppm/degree.

For $0.67 each, $0.38 in strip of 100, you get 10 ppm/degree

Cheapest 0.05% is $2.33, $1.58 in strip of 100. 5 ppm/degree.

Order today, ships today. ERJ-PB3B1002V – 10 kOhms ±0.1% 0.2W, 1/5W Chip Resistor 0603 (1608 Metric) Automotive AEC-Q200, Pulse Withstanding Thick Film from Panasonic Electronic Components. Pricing and Availability on millions of electronic components from Digi-Key Electronics.

www.digikey.com

Order today, ships today. ERA-3VRW1002V – 10 kOhms ±0.05% 0.125W, 1/8W Chip Resistor 0603 (1608 Metric) Anti-Sulfur, Automotive AEC-Q200 Thin Film from Panasonic Electronic Components. Pricing and Availability on millions of electronic components from Digi-Key Electronics.

www.digikey.com

Order today, ships today. TNPU060310K0AZEA00 – 10 kOhms ±0.05% 0.1W, 1/10W Chip Resistor 0603 (1608 Metric) Anti-Sulfur, Automotive AEC-Q200, Moisture Resistant Thin Film from Vishay Dale. Pricing and Availability on millions of electronic components from Digi-Key Electronics.

www.digikey.com

I've used other value of same family part hoping to get value tracking (ratio having better ppm per degree.)

Have to watch out for self-heating, can't run one hotter than the other and get as good tracking.

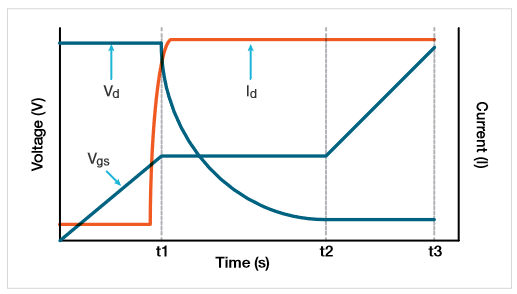

Also, that ppm isn't a straight line from minimum to maximum temperature. It follows an "S" curve, because it is tuned to stay as close to nominal value as possible. A part with 50 ppm spec and 100 degree operating range would span 5000 ppm (0.5%), or +/- 0.25% from nominal. It could be nominal at 25 degree temperature, and +0.25% at 50 degrees.

For ratio of similar values I've put two or three of same part in series or in parallel.