iamrich

Solar Addict

How does shipping look now for 3 packs of 21.198 kWh ? Total below

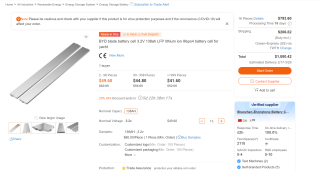

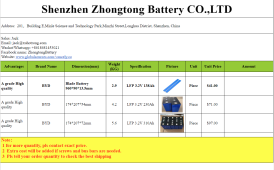

Cost / Price

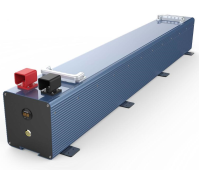

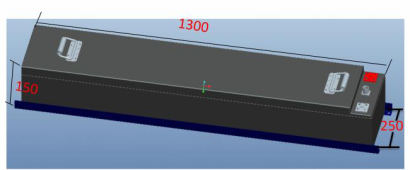

3 x 16S1P BYD Blade Battery Pack with screws and bus bars: $2,016

3 x BMS for 16S1P: $330

Shipping from ShenZhen China to Miami Florida: $638

Total: $2,984

In reality, it is all what you are willing to pay. Prismatic cells are right around $166 per kwh delivered (+/- $20). Figure the BMS is going to be the same for either, so taking your numbers above, you are looking at $112 per kwh delivered for the cells (if I did the math correctly). I would consider that a great deal assuming these are genuine BYD cells, and they make it across the ocean. You will have additional costs putting these together (banding/compression, wiring, some kind of enclosure, etc.), but I think the price is very tempting.

The current plug and play go to battery is the EG4 5.12kwh (48v/100ah) and that is right at $300 per kwh. It comes ready to use (BMS, breaker, load resistor, etc.).