Has any of you designed and built a Coulomb counter for LiFePO4 batteries, to keep track of SOC?

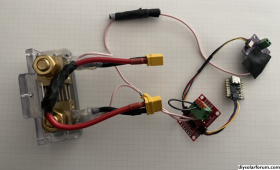

My current lead acid setup already has a voltage and current sensor connected to an Arduino with a screen. Soon I'll switch to LFP, so why not take some time and implement a SOC monitor in software, just because it is fun. See if I can match the Coulomb counter in the BMS. Just need to figure out a good algorithm for LiFePO4.

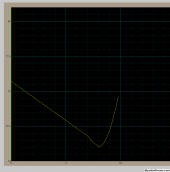

A very simplified model is just energy in, minus energy out, minus losses (how much?), minus self discharge (how much?), plus keeping track of the upper and lower voltage tail ends and then resetting the SOC to 100%/0% when those happen.

My current lead acid setup already has a voltage and current sensor connected to an Arduino with a screen. Soon I'll switch to LFP, so why not take some time and implement a SOC monitor in software, just because it is fun. See if I can match the Coulomb counter in the BMS. Just need to figure out a good algorithm for LiFePO4.

A very simplified model is just energy in, minus energy out, minus losses (how much?), minus self discharge (how much?), plus keeping track of the upper and lower voltage tail ends and then resetting the SOC to 100%/0% when those happen.

Last edited: