I am brainstorming designs for a DIY 100w TEG that I want to build this winter. I think it will be a good solution because our primary heating source is a wood fired cooking oven that is on all day during the harshest part of winter and a thermoelectric generator will provide us with constant and reliable power when the panels are covered in snow.

What are your thoughts on a simple design?

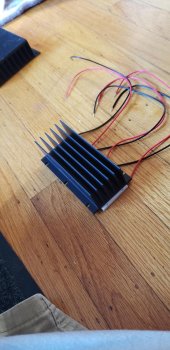

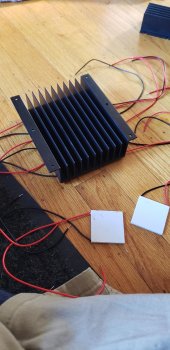

My thoughts is to have device that will fit on one ring of the cook stove and can be placed to the side easily when not in use. The ring is cast iron with fins on the bottom that directly touch the flames. I can mill and polish the ring to make a good enough contact, if needed. Im also considering whether the tegs should be clamped with an extra plate or exposed to be in direct contact with the ring. What do you think?

Since I cant get circular TEGs I would like to approximate the shape by using square ones that can extend off of the ring a little bit. Would it be a good design to simply glue/clamp the TEGs to the underside of a sealed cooking pot with an water inlet and outlet attached? With maybe a heat sink glued on the inside..

Ive heard that you need silver solder.. What about just clamping the wires together? Or leaving the wires long and extend them to a cooler spot to make the join?

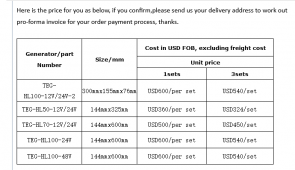

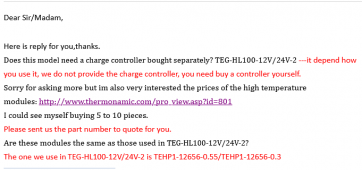

What is a good charge controller? Ive seen threads here that are indicating that solar mppt controllers work. Cheap is fine, even if its a bare circuit board I can make a box for it. It would be nice with a display telling me watts and kwh.

What are your thoughts on a simple design?

My thoughts is to have device that will fit on one ring of the cook stove and can be placed to the side easily when not in use. The ring is cast iron with fins on the bottom that directly touch the flames. I can mill and polish the ring to make a good enough contact, if needed. Im also considering whether the tegs should be clamped with an extra plate or exposed to be in direct contact with the ring. What do you think?

Since I cant get circular TEGs I would like to approximate the shape by using square ones that can extend off of the ring a little bit. Would it be a good design to simply glue/clamp the TEGs to the underside of a sealed cooking pot with an water inlet and outlet attached? With maybe a heat sink glued on the inside..

Ive heard that you need silver solder.. What about just clamping the wires together? Or leaving the wires long and extend them to a cooler spot to make the join?

What is a good charge controller? Ive seen threads here that are indicating that solar mppt controllers work. Cheap is fine, even if its a bare circuit board I can make a box for it. It would be nice with a display telling me watts and kwh.