Solarisium

New Member

Hi Solar folks!

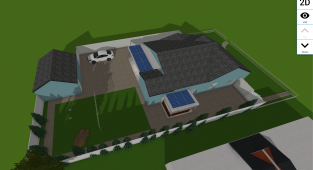

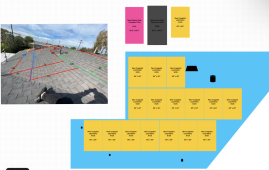

I just started my journey! Yep it is a journey for a true DIYer. Here is design (still a draft):

I have a clear idea of what I am going to install: a 4.5 KW SMA grid tie system. no power optimizer, no micro inverter, no battery or storage devices. Plain and simple.

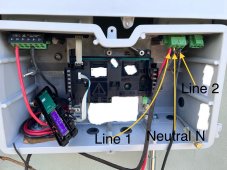

I will probably use new or unused panels to generate 4.5kw. will connect them in parallel/series to get to 240 volts. Will run it to a 5.0 kw SMA string inverter and from there to a rapid shutdown switch and to the fuse panel.

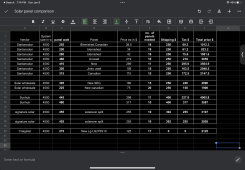

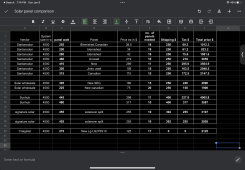

Right now I am searching for the right panel and inverter to order. Might use unused blemished 10x450w OR new 16x250 w given the space on my roof.

regarding the NEM application: I started the online application on SCE. SCE has all the forms you need to fill out and an online application tool. It’s a great resource for DIYers to find out what forms and information are needed to get their NEM approved. I have not submitted my application just yet as I am still finalizing the design and need to find a whole seller online to order the parts.

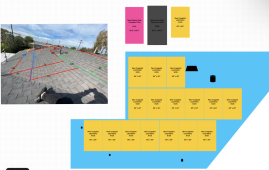

In order to draft my design I took a photo of my south facing roof. Then edited the photo and drew lines to designate species for solar panels. Went to the roof again and measured everything. Used Freeform app on my iPad and drew this to scale. finally I used a spreadsheet to find out how many of each panel type I need.

Then tried to fit them on my design to find out if sufficient number of panels can fit to generate ~4.5kw. The small black shapes are the plumbing vents or attic vents since they are the obstacles, needed to be identified in the design.

My timeline is April first. On April 13 the NEM 3.0 will be effective, which means longer payoff times. There are two pieces of the work that I haven’t completed my research. The local township permit and the racking system.

I appreciate if anyone has any advice for me at this point.

p.s. I am hoping my post is in the right place. If not, will move it.

I just started my journey! Yep it is a journey for a true DIYer. Here is design (still a draft):

I have a clear idea of what I am going to install: a 4.5 KW SMA grid tie system. no power optimizer, no micro inverter, no battery or storage devices. Plain and simple.

I will probably use new or unused panels to generate 4.5kw. will connect them in parallel/series to get to 240 volts. Will run it to a 5.0 kw SMA string inverter and from there to a rapid shutdown switch and to the fuse panel.

Right now I am searching for the right panel and inverter to order. Might use unused blemished 10x450w OR new 16x250 w given the space on my roof.

regarding the NEM application: I started the online application on SCE. SCE has all the forms you need to fill out and an online application tool. It’s a great resource for DIYers to find out what forms and information are needed to get their NEM approved. I have not submitted my application just yet as I am still finalizing the design and need to find a whole seller online to order the parts.

In order to draft my design I took a photo of my south facing roof. Then edited the photo and drew lines to designate species for solar panels. Went to the roof again and measured everything. Used Freeform app on my iPad and drew this to scale. finally I used a spreadsheet to find out how many of each panel type I need.

Then tried to fit them on my design to find out if sufficient number of panels can fit to generate ~4.5kw. The small black shapes are the plumbing vents or attic vents since they are the obstacles, needed to be identified in the design.

My timeline is April first. On April 13 the NEM 3.0 will be effective, which means longer payoff times. There are two pieces of the work that I haven’t completed my research. The local township permit and the racking system.

I appreciate if anyone has any advice for me at this point.

p.s. I am hoping my post is in the right place. If not, will move it.