Nobody else replying? Really? I thought this was a very popular tool....EBC-A40. wow Just us

I am not the BEST source for my first time with ebc-a40. but this is what I found. I don't think would try more than 1 cell at a time for initial charging.... that comes at the end when you tie them in parallel after letting them rest for 12-24hours.

That was the charging recommendation from my original 12v battery sets. initial charge separate, then Tie in parallel, after 12-24hour of rest in parallel, charge again while all are still hooked in parallel My 12v packs made it about a year and a half by doing that. My cells were doing great until started doing more and more mppt solar charging. To me It is embarrassing to charge solar battery bank with grid. Mppt Solar with small array is not stable constant charge though. probably be someone cry over that statement. You can watch solar charge current go up and down all day. That is just not good way charge batteries in my opinion. IF the solar array can put out more current than the solar charging needs then probably golden. Does that really happen with small arrays? NO. I'm thinking the solar panel array needs to be maxed out per inverter - mppt manual. Small array - current is all over the place. Not good for battery charging imho not a constant. I've watched my cells with blue tooth and watched mppt pv and current - solar assistant-victron bt shunt-inverter - victron mppt various combinations ..... the whacky cells started when I began solar charging. been using my 48 lifepo charger. I think need more panels in parallel. probably 2-3 more strings solar panel to get current up but there is a limit to that amp with new inverters too. Mine new inverter is high pv and low current for built in mppt's. They take the high pv and use it with low current input. PPL with big arrays whine too.

Battery chargers usually set a current then raise the voltages to a desired set point...... once that set point is hit for voltage the charge current will began to drop until the charging is complete - charger shuts off..... done by algorithms because lifepo specific charging is required. lead acid is similar for what it needs.

Be something if ppl having battery problems are due to solar charging. Read reports here over and over. Just my notice.

![20240710_202527[1].jpg 20240710_202527[1].jpg](https://diysolarforum.com/data/attachments/228/228143-195e56716a9e3a954be7d639659e26ca.jpg)

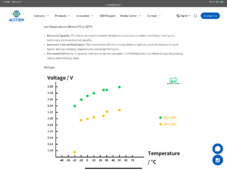

With EBC-A40 ......... It is nice to see a graph.

My EBC appears work..... sorry you got a bad one …takes long time just to charge a single 100ah cell ~2 hours+ even if start with broken down supposed charged battery cells. I got tired of my 12volt packs not charging properly and broke down 1 battery - top balanced cell in 1 and have 3 more 12v to go. I will be stripping the cells and building back cells 16s and 48v jk bms for nom pack. The runners had to go. I hope they stay gone. Fingers crossed.

I do not recommend using 12v packs in 48v series and it lead me to here buying ebc-a40. Will Prowse agrees buy 48v battery for 48v and he has lot more experience with them than me. I'd listen to him.

My 12v packs had arrived 0 SOC when purchased them. Had hard time waking one of them up and it had lost all the setting from bms. Had get replacement. Anyway am going to build the rescued 12v cells into 48v pack. The ebc-40a is what I bought to rework these cells. It takes long time to do cells. Probably why they don’t do it when building these cheap 12v batteries just toss them in. Might match might not. Got their money. I got my cheap battery. I highly recommend blue tooth see what bms are doing inside with any battery. I know exactly where the trouble cells are.

Will Prowse was right - the batteries stink like crazy when broken down. It “smells like old harbor freight electrics” burnt up but stronger when break a battery down. . Those cells had lot of silicon on bottom - blocks - foam sides - tough get out. The top popped right off with a wood chisel - hammer starting on small side …. then grabbed ripped rest way off. The lids were not put on real solid. I was afraid they had used a plastic melt glue but was only held on with silicon. Could reuse cases and may for lower boxes-to hold repurposed cells.

Seen Any 100ah diy boxes?

Again this was my initial first time using that ebc tester. I trust it…watched it do 3 cells building trust …..went to sleep woke up …. it had finished last battery cell and automatically shut down…. faith. that cell had acted good so knew it wasn't a runner.

When you do a runner cell they get little wonky I just shut down let it sit for 30 minutes or so then restarted program which ran - balanced perfectly. I charged 3.6v 20amps 2 amp shut off for these 100ah lifepo cells

3.45v was not working with runner….so to set them all the same went 3.60v top balance…the higher voltage worked.

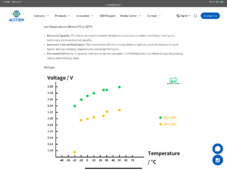

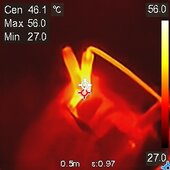

You need to watch temps. They are suppose to be done at specific temps Read it somewhere. A Texas Instrument Physic degree chemical engineer did a paper on lifepo. I can’t find that reference no where now. Closest thing seen was a search on youtube Goofy Andy’s Off Grid Garage did a video on this charger. Think he mentioned temps too. Internal cell Resistance changes with temps. Right?

I am not sure if Will did a video on it - didn't look. I'm guessing he has a video on it.

Again trying to top balance that runner cell took higher voltage to bring it in line - make break the resistance …I dunno.

Reading bunch of post on here about batteries TO ME notice most charging troubles -weird battery problems come from mppt type solar panel charging. The friggin current is all over the place some times. Think I need to run a parallel string or 2. No constant….with solar charging.

The EBC-A40 basically has set current 20amp my setting with rising voltage until it hits user set voltage ie: mine 3.60v then it rides until algorithm drops current subject to voltage at a constant …the runner cells try to drop voltage when current drops. So again, I let it run until current got to about 10 amps drop from 20 = half set.. It was fighting to keep constant voltage. I knocked it down for about 30 minutes….rest. Came back voltage was around 3.37 next go charged up 3.60v like champ …made graph above. Wish had charted the runner to show. It was a fighter. I also run through an old laptop - graphs. you can save all of them to compare at later date when rebalance.

Make sure you put in the period for voltages. It would be nice if it went up to 60v and 40 amps.

Dual use charge everything. It is limited to 5 volt 40 amps. I felt 20amps was aggressive and the runner had me nervous it might swell - pop do something crazy.

that graph was a crazy thing to see. I looked the cells over will free put them in parallel once all 16 are done and rebalance them again. I've watched Ray builds cool things he said it takes a long time for that too. Again why they don't really check these cells in cheap batteries - my opinion. Takes a long time.

Recommend find that top balance guide on here as it was interesting. I tried charging the 12v packs max when arranged in my 48v series before tearing down…helps process go faster. I don’t feel like messing with full features ….of charge discharge then final charge again .... tired but the ebc tester will do it all in multi-test. automatically….Andy off grid garage video was good. Suggest you look for and watch it.. too The Texas Instrument guy recommended top balancing once a year. Wished could find that website - lifepo cell paper. Good read.

Increased resistance why temp needs to be normalized to get even balances.

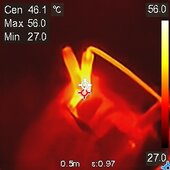

warm these are hard to get good clamp action so might be better ring terminal and nut it down remove clips. I think might be best to put voltage wire on top of current lead with ring lug terminals on both too. it was pain to get little voltage lead to clip good a few times. Makes sure it is reading good voltage-was double checking with my meter darn near spot on. Current cable clamp towards end of test... was around ~115f Thermal below

I started with it so am not changing anything now - consistency with everything. After this pack is built will raise blade make the ring lug terminal change to ebc-a40.

I am gaining experience to do my other NEW cells 16s 280ah These old cells are the learning part. The new cells are again 280ah so they will take a lot longer.... than 100ah cells

BTW Aliexpress has a charge with different specs but could not confirm it- comes with 120v ac plug.

"""EBD-B10H 12V-72V 24V36V48V60V Lithium Lead Acid Battery Capacity Tester 10A Discharge Current Support PC Software Test ~$200""" With only 10a will be even slower.

Watching batteries charge is not my ideal of a good time. I would prefer to set and forget when done come back and ready to party. I didn't want a new hobby I wanted an emergency back up for some power when the neglected grid goes down. Again majority of ppl report battery problems after solar charging. Just look at reports. Might be something to look at and watch to see how stable your voltage -current is going into batteries -cells with solar charger.

Clear as mud. Sorry. Best I can do in this quick post. I gave $178 plus tax on amazon. This is my journey of why and how I got here.

![20240710_202527[1].jpg 20240710_202527[1].jpg](https://diysolarforum.com/data/attachments/228/228143-195e56716a9e3a954be7d639659e26ca.jpg)