NovicePV

New Member

Hi everyone,

Lots of info in the forum here that I've been reading through but I (definitely!) could use some advice. I've basically taken the Energy Advisor report (and yes, I know it is likely very overstated for energy usage) and designed a (multiple) rooftop/garagetop PV array using Skelion for modeling solar. This is of course, going to be Net Metered.

The electrical service entrance is 400A going to the detached garage, but will split into 3. One 200A panel for the Main Suite, 100A for the Secondary Suite, and 100A for the Garage. (Leviton Smart Panel doesn't have "in-between" ampacity sizes, unfortunately.) One important note here is that the 200A and 100A panels will be in house in their respective suites/areas and the 100A would be in the detached garage.

In the longer run, I'd like to be able to battery back everything (more or less) with Smart Breakers installed in circuits for large loads that I'd want to shed: heat pump washer/dryer, combo-oven, EV charger, that sort of thing. The house is all electric with 2 x heat pumps (one for DHW and radiant heat, one dedicated for AC although technically, it can heat as well). Despite this, my suspicion is that I would rarely if ever actually hit over 12KW for any length of time in regular use, less so during an "outage" with loads shed. Another thing to note, I haven't quite figured out yet which panel I should hang my 2 x Heat Pumps since they are right by the garage. The options are of course, placing another panel in the garage that would break out X Amps for heat pumps, before continuing to the main suite panel in the house; or putting them on the garage panel (along with EV). I can probably get away with 4.8KW charging for the EV (actually I could probably get away with L1 charging!) because we don't travel all that much (and an EV is part of future plans...don't have one at the moment).

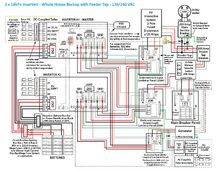

In any case, would you all recommend 1 x EG4 18K on the 200A Main Suite, and putting the 100A Secondary Suite and 100A Garage Panel on the 2nd (and independent, non-slaved) 18KPV. If I do this and have the heat pumps on the 100A garage panel, am I able to have the 18KPV's share battery banks? Or must I wire batteries completely independently to each 18KPV?

Or do I can run the full 400A service into 2x18KPV in parallel (or should it be 3 since there's some slight derating necessary?), then output 200A to main suite, 100A to secondary suite, and 100A to the garage? Would I basically follow Page 35 of the EG4 18kPV manual but with larger fuses for the input and output combiners? I'm guessing using 400A capable combiners, transfers etc will be more expensive?

I'm also open to "better ways" of setting this all up. The house isn't large (actually slightly smaller than Vancouver standard lot, 33'x110') but it is getting very "packed" so in some sense, less is more. BTW, I also can't place the Inverter and Batteries outside (like I wanted to) as I have a number of "site hardships" which include a pole mounted transformer (no panels within 6m cylinder) which necessitated shifting my garage over Eastward...meaning inverter/batteries would get a lot of direct sun (albeit Vancouver sun vs. Texas heat) during summer months. So, I'll have to stuff them inside the garage as well...sigh.

Thanks in advance!

Lots of info in the forum here that I've been reading through but I (definitely!) could use some advice. I've basically taken the Energy Advisor report (and yes, I know it is likely very overstated for energy usage) and designed a (multiple) rooftop/garagetop PV array using Skelion for modeling solar. This is of course, going to be Net Metered.

The electrical service entrance is 400A going to the detached garage, but will split into 3. One 200A panel for the Main Suite, 100A for the Secondary Suite, and 100A for the Garage. (Leviton Smart Panel doesn't have "in-between" ampacity sizes, unfortunately.) One important note here is that the 200A and 100A panels will be in house in their respective suites/areas and the 100A would be in the detached garage.

In the longer run, I'd like to be able to battery back everything (more or less) with Smart Breakers installed in circuits for large loads that I'd want to shed: heat pump washer/dryer, combo-oven, EV charger, that sort of thing. The house is all electric with 2 x heat pumps (one for DHW and radiant heat, one dedicated for AC although technically, it can heat as well). Despite this, my suspicion is that I would rarely if ever actually hit over 12KW for any length of time in regular use, less so during an "outage" with loads shed. Another thing to note, I haven't quite figured out yet which panel I should hang my 2 x Heat Pumps since they are right by the garage. The options are of course, placing another panel in the garage that would break out X Amps for heat pumps, before continuing to the main suite panel in the house; or putting them on the garage panel (along with EV). I can probably get away with 4.8KW charging for the EV (actually I could probably get away with L1 charging!) because we don't travel all that much (and an EV is part of future plans...don't have one at the moment).

In any case, would you all recommend 1 x EG4 18K on the 200A Main Suite, and putting the 100A Secondary Suite and 100A Garage Panel on the 2nd (and independent, non-slaved) 18KPV. If I do this and have the heat pumps on the 100A garage panel, am I able to have the 18KPV's share battery banks? Or must I wire batteries completely independently to each 18KPV?

Or do I can run the full 400A service into 2x18KPV in parallel (or should it be 3 since there's some slight derating necessary?), then output 200A to main suite, 100A to secondary suite, and 100A to the garage? Would I basically follow Page 35 of the EG4 18kPV manual but with larger fuses for the input and output combiners? I'm guessing using 400A capable combiners, transfers etc will be more expensive?

I'm also open to "better ways" of setting this all up. The house isn't large (actually slightly smaller than Vancouver standard lot, 33'x110') but it is getting very "packed" so in some sense, less is more. BTW, I also can't place the Inverter and Batteries outside (like I wanted to) as I have a number of "site hardships" which include a pole mounted transformer (no panels within 6m cylinder) which necessitated shifting my garage over Eastward...meaning inverter/batteries would get a lot of direct sun (albeit Vancouver sun vs. Texas heat) during summer months. So, I'll have to stuff them inside the garage as well...sigh.

Thanks in advance!