timselectric

If I can do it, you can do it.

- Joined

- Feb 5, 2022

- Messages

- 19,792

I would definitely recommend a soft start.

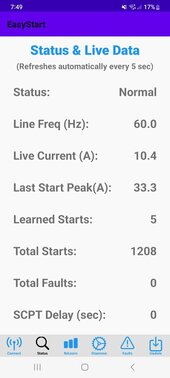

I have been using the EasyStart brand on two AC units. A 12k btu window unit, and a 3T central air unit.

Both have functioned flawlessly and reduced startup surge by 2/3.

My system didn't have any problems starting them, without the soft starts. But reducing the surge is better for everything. (Breaker, wiring, contractors, inverter and compressor) and I believe it will increase the lifespan.

These units would probably all come with soft starts, if it didn't increase the cost so much.

The compressor doesn't need that much power to start. But if it's available (massive grid available), it will take it.

The compressor manufacturer assumes that it will be connected to the grid. So there's no need to add the increase in cost.

I have been using the EasyStart brand on two AC units. A 12k btu window unit, and a 3T central air unit.

Both have functioned flawlessly and reduced startup surge by 2/3.

My system didn't have any problems starting them, without the soft starts. But reducing the surge is better for everything. (Breaker, wiring, contractors, inverter and compressor) and I believe it will increase the lifespan.

These units would probably all come with soft starts, if it didn't increase the cost so much.

The compressor doesn't need that much power to start. But if it's available (massive grid available), it will take it.

The compressor manufacturer assumes that it will be connected to the grid. So there's no need to add the increase in cost.