You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Exceeding Inverter Limits

- Thread starter LLLL

- Start date

Rednecktek

Solar Wizard

Max PV Voltage is a HARD limit. Hard like granite or AR400 steel or the look your wife gives you when you come back from the heavy equipment auction.Would you go ahead with this setup? Do you consider this a risky setup?

Do NOT exceed!

JWLV

-.-. --.-

- Joined

- May 27, 2020

- Messages

- 579

The VOC numbers on solar panels are stated at a standard environment of 25 degrees Celcius. If it is colder than that, the VOC is much higher. If it is warmer than that, the VOC is lower.

Given that your solar panels in series has a total of 264 VOC, if you live in a hot climate year round and it never gets cold, then you might be able to get away with using your current equipment.

You can easily halve your VOC by arranging your panels in two parallel strings. Then you'll have no problems at all with the VOC.

Given that your solar panels in series has a total of 264 VOC, if you live in a hot climate year round and it never gets cold, then you might be able to get away with using your current equipment.

You can easily halve your VOC by arranging your panels in two parallel strings. Then you'll have no problems at all with the VOC.

Just divide them up aka don't put them all in the same string (series).

If you have 8 making that voltage then just do two strings of 4.

4s2p.

panel1-4> 132volts

.......................> charge controller

panel5-8> 132 volts

The panel calculator in my signature will help you decide how to set them up.

If you have 8 making that voltage then just do two strings of 4.

4s2p.

panel1-4> 132volts

.......................> charge controller

panel5-8> 132 volts

The panel calculator in my signature will help you decide how to set them up.

CaliSunHarvester

Solar Enthusiast

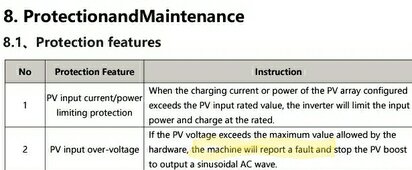

The general rule of thumb is that your inverter Max Input voltage must be greater than Voc x 1.2, otherwise the inverter will shut down (if you are very lucky) or fry (more likely).

OH NO!!

I have a (newer) installation with used panels that have a Voc of 37.8V and the inverter allows up to 500V. I have 2 strings of 13 panels.. thinking 13 * 37.8V = 491.4V which is under 500V

The temperature early in the morning is probably 10Celsius these days.. 15C below the rated temperature. How much will the Voc actually rise?

And if I always have an inverter charger on it, with a battery and loads, wouldn't that mean that I never receive Voc? As it is never an "open circuit"?

As this is a new installation, I have spent quite some time looking at the inverter's display including at 6:30am.. and I usually see a voltage around 300V combined.. meaning 23V per panel. In the middle of the day it goes as high as 370V. Pretty sure I never saw a 4xx voltage.

When looking at the lowest possible temperature.. only temperatures after sun-rise have to be considered, right?

Google response:

"This means that for every degree change in temperature, the module's Voc will change in the opposite direction by 0.35%. "

20 degrees C lower temperature = 7% higher Voc .. in my case Voc would be 40.4V per panel or 525V for a full string.

I'm going to shut down my breaker right now!

The Google response is from a 2012 article. But my panels are almost that old (260W panels).

EDIT: I looked up the temp coefficient:

Temperature Coefficient of Voc -0.27 %/°C

Glad I ran into this thread in time.

Last edited:

CaliSunHarvester

Solar Enthusiast

I have some spare panels (same model). What if I measure Voc tomorrow morning at sunrise? Is there a chance that Voc has degraded since they are 10 years old?

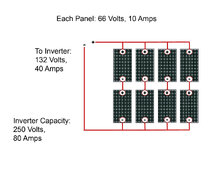

If the panels are 66 volts each thats to high. Each string having 4 panels will be 264 volts. 3 is the most you could do in series. What's the minimum voltage of the inverter?Do I have this layout correct/best?

If yes, can I use 12 gauge wire for this? (it needed to travel about 40' to the inverter)

ThanksView attachment 186830

Rednecktek

Solar Wizard

Isn't that sketch a 2s4p setup? That should be plenty fine for 66v panels on a 250v controller, unless it's one of those high voltage needs 120+ volts to start AIO's that are getting to be more common nowadays.If the panels are 66 volts each thats to high. Each string having 4 panels will be 264 volts. 3 is the most you could do in series. What's the minimum voltage of the inverter?

If that's the case, can you get one more panel and set them up as a 3s3p?

zanydroid

Solar Wizard

Voc is relevant because it becomes an open circuit whenever the input transistors turn off while doing their SMPS switching magic. And if your battery is topped off they would definitely switch off for long periods of time.And if I always have an inverter charger on it, with a battery and loads, wouldn't that mean that I never receive Voc? As it is never an "open circuit"?

Incidentally, those are also the things that will get fried by the voltage.

Is your 500V maximum VOC limit or max operating range?

Never mind I didn't see it as 2 serial at first glance so it would be fine that way.Isn't that sketch a 2s4p setup? That should be plenty fine for 66v panels on a 250v controller, unless it's one of those high voltage needs 120+ volts to start AIO's that are getting to be more common nowadays.

If that's the case, can you get one more panel and set them up as a 3s3p?

Last edited:

CaliSunHarvester

Solar Enthusiast

What’s the coldest on record at your location?OH NO!!

I have a (newer) installation with used panels that have a Voc of 37.8V and the inverter allows up to 500V. I have 2 strings of 13 panels.. thinking 13 * 37.8V = 491.4V which is under 500V

The temperature early in the morning is probably 10Celsius these days.. 15C below the rated temperature. How much will the Voc actually rise?

And if I always have an inverter charger on it, with a battery and loads, wouldn't that mean that I never receive Voc? As it is never an "open circuit"?

As this is a new installation, I have spent quite some time looking at the inverter's display including at 6:30am.. and I usually see a voltage around 300V combined.. meaning 23V per panel. In the middle of the day it goes as high as 370V. Pretty sure I never saw a 4xx voltage.

When looking at the lowest possible temperature.. only temperatures after sun-rise have to be considered, right?

Google response:

"This means that for every degree change in temperature, the module's Voc will change in the opposite direction by 0.35%. "

20 degrees C lower temperature = 7% higher Voc .. in my case Voc would be 40.4V per panel or 525V for a full string.

I'm going to shut down my breaker right now!

The Google response is from a 2012 article. But my panels are almost that old (260W panels).

EDIT: I looked up the temp coefficient:

Temperature Coefficient of Voc -0.27 %/°C

Glad I ran into this thread in time.

Then punch in the numbers here:

Solar Panel Maximum Voltage Calculator - Footprint Hero

Calculate the maximum open circuit voltage of your solar array. Find your max solar panel voltage to correctly size your solar charge controller.

footprinthero.com

footprinthero.com

My I guess is you’d probably need to go down to 11 panels maximum per string.

CaliSunHarvester

Solar Enthusiast

Reducing from 13 to 11 would definitely be safe, that's what I calculated last night as well.

"coldest on record"

would that include night temperatures or only temperatures while there's sunlight?

It may be necessary to consider even midnight temperatures, as there could be some freak situation where someone points massive floodlights at midnight on my roof from a helicopter. Or a lightning storm. Really bright moon? The panels are mounted almost flat, BTW.

So, sun is rising right now. Temperature is 11C. I pointed 5 worklights at a spare panel and measured Voc of 24.8V. The string on the roof showed ten minutes ago 126V (~10V per panel) and now 260V (20V per panel).

I will wait until noon and measure Voc then.

"coldest on record"

would that include night temperatures or only temperatures while there's sunlight?

It may be necessary to consider even midnight temperatures, as there could be some freak situation where someone points massive floodlights at midnight on my roof from a helicopter. Or a lightning storm. Really bright moon? The panels are mounted almost flat, BTW.

So, sun is rising right now. Temperature is 11C. I pointed 5 worklights at a spare panel and measured Voc of 24.8V. The string on the roof showed ten minutes ago 126V (~10V per panel) and now 260V (20V per panel).

I will wait until noon and measure Voc then.

The Inverter, Growatt Off Grid SPF 3000TL LVM-ES, needs 120vdc to start; would the 132 volts of this setup do that job?Isn't that sketch a 2s4p setup? That should be plenty fine for 66v panels on a 250v controller, unless it's one of those high voltage needs 120+ volts to start AIO's that are getting to be more common nowadays.

If that's the case, can you get one more panel and set them up as a 3s3p?

Also, would 12 gauge wire work for these specs, running 40' to the inverter?

CaliSunHarvester

Solar Enthusiast

Also, would 12 gauge wire work for these specs, running 40' to the inverter?

hi, I wanted to apologize for kind of hijacking your thread. Trying to contribute now.

The wire gauge is determined by the Amps, primarily. Thicker wire will have less voltage loss though. When you use a voltage loss calculator, you will need to put in the full length of the circuit which would be round trip = 80 feet.

Your sketch shows 40As, and 12 gauge is not enough for that.

14 AWG = 15 Amps

12 AWG = 20 Amps

10 AWG = 30 Amps

8 AWG = 40 Amps

That's the problem with parallel strings. The wire gets more expensive and also more difficult to handle (bend) etc.

You can still use the 12 AWG wire for each string, but from the combiner box to the MPPT, you will need the thicker one.

The other thing.. I just wrote it.. combiner box.

You will see items on Amazon that combine as much as 4 strings in one just by merging the wires, but that is dangerous. More than 2 strings, you need the combiner box with fuses.

In my older setup, I also have 4 strings due to my MPPTs voltage limit:

zanydroid

Solar Wizard

Reducing from 13 to 11 would definitely be safe, that's what I calculated last night as well.

"coldest on record"

would that include night temperatures or only temperatures while there's sunlight?

It may be necessary to consider even midnight temperatures, as there could be some freak situation where someone points massive floodlights at midnight on my roof from a helicopter. Or a lightning storm. Really bright moon? The panels are mounted almost flat, BTW.

So, sun is rising right now. Temperature is 11C. I pointed 5 worklights at a spare panel and measured Voc of 24.8V. The string on the roof showed ten minutes ago 126V (~10V per panel) and now 260V (20V per panel).

I will wait until noon and measure Voc then.

View attachment 186871

Is that voltage with MPPT active?

Is that with no cells shaded? That voltage is pretty weird, you have 60 cell panels there, Voc should not be that low. Unless somehow somebody shorted one bypass diode on the majority of panels you have there. Or bypass diode had failed closed. You are getting 2/3 of voltage which something weird happening with bypass diode is consistent with. BTW removing a panel OR shorting to bypass a diode are both ways to drop the voltage.

Take it out and put it on the ground during the day.

You should probably create your own thread and link it.

Yeah don't trust this.Per manual, there is at least a rudimentary protection, and the unit has never thrown a fault code, so I think I didn't damage anything.

What is the overhead of removing one panel?

Similar threads

- Replies

- 2

- Views

- 120