I have confirmation from Sim at Growatt that the replacement MPPT control board that I ordered is incorrect. (Amos assigned the case to Simphiwe, who goes by Sim.) I will be shipping it back to Ian and am looking to get a replacement from Growatt directly.

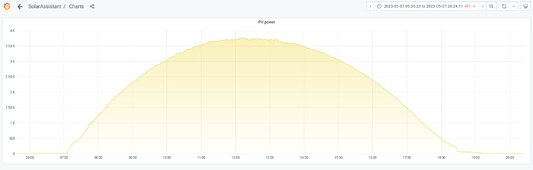

The connection that essentially blew off the board was the positive battery connection. There is a 2-wire lead from the primary battery connection to the MPPT power board. (One pair for the positive and one pair for the negative.) Closer examination of SolarAssistant's logs show that the power flow went from ~755W into the batteries to an ouput surge of ~3.1kW and then a spike to ~8.5kW before power was cut. (8.5kW is ~60A from each of the 3 batteries. This is well within the discharge spec for the cells so the BMS's weren't tripped and each battery has a 250A fuse, which of course didn't trip either.) The discharge occurred for a ~1minute period. The replacement MPPT power board, and the remaining good boards in the inverter, all have a conformal coating, so I'm leaning towards an internal board fault being the cause of the failure at this point. The failed board having the problem section blown to bits, and not having a schematic, makes a diagnosis difficult.

I will update as I have more information.

The connection that essentially blew off the board was the positive battery connection. There is a 2-wire lead from the primary battery connection to the MPPT power board. (One pair for the positive and one pair for the negative.) Closer examination of SolarAssistant's logs show that the power flow went from ~755W into the batteries to an ouput surge of ~3.1kW and then a spike to ~8.5kW before power was cut. (8.5kW is ~60A from each of the 3 batteries. This is well within the discharge spec for the cells so the BMS's weren't tripped and each battery has a 250A fuse, which of course didn't trip either.) The discharge occurred for a ~1minute period. The replacement MPPT power board, and the remaining good boards in the inverter, all have a conformal coating, so I'm leaning towards an internal board fault being the cause of the failure at this point. The failed board having the problem section blown to bits, and not having a schematic, makes a diagnosis difficult.

I will update as I have more information.