Horsefly

Solar Wizard

A couple of years ago I built an 8S 230Ah 24V battery for our cabin in the mountains of Colorado, replacing the AGM battery bank that had been there since 2017. I documented the details (with lots of photos) of the new battery build in this thread: Horsefly's Cabin Solar LiFePO4 Upgrade

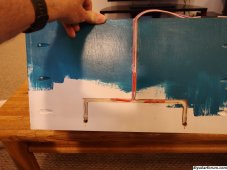

One of the key requirements of the battery was that I wanted it to be self heating over the winter, so that if anyone showed up it would be ready to go. In the process of designing and testing the battery I found it was not difficult to keep the battery between 50°F and 60°F even when the ambient temperature outside the battery box stayed close to zero. The battery was installed in the spring of 2022 (getting rid of those nasty AGM batteries for good!), and it did its job through the challenging winter of 2022/2023.

This summer we've added some loads to our cabin, most notably an 18cf refrigerator, replacing the old 8cf absorption propane refrigerator we've had for a couple of decades. Although the existing battery might be able to handle the loads, I decided to build a second battery to put in parallel with the 2021 build.

In this thread I'll try and document what I did on the second battery.

One of the key requirements of the battery was that I wanted it to be self heating over the winter, so that if anyone showed up it would be ready to go. In the process of designing and testing the battery I found it was not difficult to keep the battery between 50°F and 60°F even when the ambient temperature outside the battery box stayed close to zero. The battery was installed in the spring of 2022 (getting rid of those nasty AGM batteries for good!), and it did its job through the challenging winter of 2022/2023.

This summer we've added some loads to our cabin, most notably an 18cf refrigerator, replacing the old 8cf absorption propane refrigerator we've had for a couple of decades. Although the existing battery might be able to handle the loads, I decided to build a second battery to put in parallel with the 2021 build.

In this thread I'll try and document what I did on the second battery.