Rednecktek

Solar Wizard

Sooo I've made a few LFP batteries, but now I'm looking at a project with cells stripped from old solar generators. I see a regular 5-wire BMS leads coming out which tells me 4s BMS and I've ordered some of those, but the whole pack is wrapped up in the blue heat shrink and I'd really, REALLY like to not have to cut the pack open.

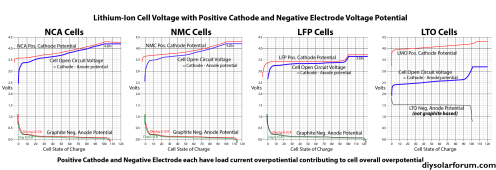

What I think I always see is that LFP batteries are 4s, 8s, 16s, and batteries using Li-Ion 18650;s is 7s, 9s, 23 & 1/3s and so on with odd numbers of cells. Is that really the case or are there 4s 18650 rigs out there? My understanding is that LFP is 3.55v fully charged but 18650's are 3.7? 3.9? 4.1?

I guess I need to know so when it comes time to program the battery I can get the settings right. So, is there some sort of dead giveaway or something to make sure what I think is a 4s LFP pack really is a 4s LFP pack without cutting the battery apart?

Thanks y'all!

What I think I always see is that LFP batteries are 4s, 8s, 16s, and batteries using Li-Ion 18650;s is 7s, 9s, 23 & 1/3s and so on with odd numbers of cells. Is that really the case or are there 4s 18650 rigs out there? My understanding is that LFP is 3.55v fully charged but 18650's are 3.7? 3.9? 4.1?

I guess I need to know so when it comes time to program the battery I can get the settings right. So, is there some sort of dead giveaway or something to make sure what I think is a 4s LFP pack really is a 4s LFP pack without cutting the battery apart?

Thanks y'all!