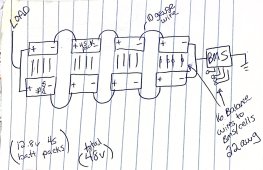

I have 48 Valence U27-12XP LiFeMgPO4 batteries. Each battery has 4 cells inside and NO INTERNAL BMS. I have pulled out the balance wires from inside and connected to a JK 16s 200a BMS (4 packs in series, 16s total cells configuration) and this works great for one 16s 48v string. but now I want to add in 11 more strings.

Currently just running a growatt 3k inverter, will expand eventually but for now the biggest load I run is my EV charger (12A @ 120vac) + a few other devices, rarely ever go over 2500watt load.) Also have a Victron Shunt and Cerbo.

I am considering doing a 4s12p setup for the batteries (if you count the cells it would be 16s12p). Would I need to do 12x 16s BMS's all in parallel to run this pack? How else can I monitor all the cells?

In theory I could parallel every single row of cells and run it all through one BMS but the balance wires are small and that doesn't seem safe to have that many cells paralleled.

Whats a good starting point?

Currently just running a growatt 3k inverter, will expand eventually but for now the biggest load I run is my EV charger (12A @ 120vac) + a few other devices, rarely ever go over 2500watt load.) Also have a Victron Shunt and Cerbo.

I am considering doing a 4s12p setup for the batteries (if you count the cells it would be 16s12p). Would I need to do 12x 16s BMS's all in parallel to run this pack? How else can I monitor all the cells?

In theory I could parallel every single row of cells and run it all through one BMS but the balance wires are small and that doesn't seem safe to have that many cells paralleled.

Whats a good starting point?