Hello Everybody,

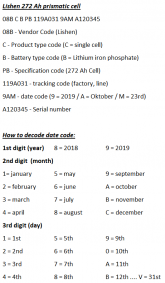

I ordered 16 Lishen 272 cells at Basen at the end of December 2020. They arrived on February, 18th. Here is what a figured out in the last two days:

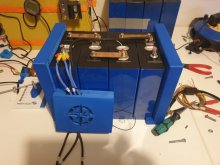

1. They were packed in 4 boxes a 4 cells verry well with big foma all around. I guess you can drop the box from at least 3 feed and nothing will happen. Good!

2. They came with busbars, studs and nuts. Good!

3. In one box was a note that they had to wrap them at Basen with theyr own staff. They came from the factory without PVC shrink because they were in a hurry? That sounds strange and I cant believe it. Not good!

4. 15 cells look the same with a clear valve window, one looks different with a blueish window. I guess they mixed cells from different manufacturers or production lines. Not good!

5. One cell has the terminal rethread. It was drilled out of the center. Not good!

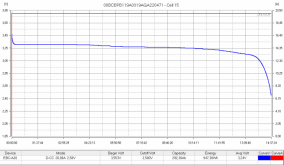

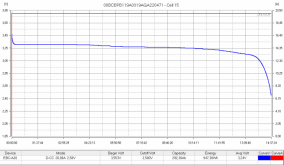

6. I did a capacity test with the first cell (with the faulty thread). First I charged it up (single cell) to 3.65 volts and a cut off current of 1 Amp. Than I let it sit for 1 hour and did a voltage drop test (3.553 volts) and tested the inner resistance (0.14 mOhm). Both values are within the specs from the datasheed (voltage drop one hour after charge >= 3.35 volts) inner resistance 0.12 mOhm +/- 0.05 mOhm). Than I discharged it with 20 Amps to 2.5 volts. That took 14 hours and 37 minutes. Capacity was 292.30 Ah. Good!

After discharging I charge up every cell with 100 Ah and stop charging. (The manufacturer recoments storage SOC within 20 - 40 %).

It will take a longer time to test every single cell by itself but I take my time and let you know.

My tester is logging the whole discharge process in a .csv file. If somebody is interested in, I can provide that file.

Gruss aus Deutschland, Michael