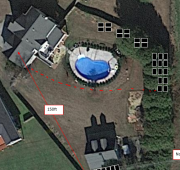

I thought i had the perfect spot to put my panels but i forgot that there is a power pole right in the middle of it! So it would be casting a shadow and i cant put panels under any type of power lines to my knowledge.

Where is this rule coming from? The power lines could well be either a short lived or consistent shade. I would think shingled or half cut would recover 50% in quite a few situations. Maybe the pole would only nuke 2-4 at a time depending on time of year and geometry. It's possible the loss from the shading could be comparable to the extra ground mount cost.

I'd create a post asking for shadow prediction apps, I saw a few posted here, I didn't save them because I know they won't do me any good.

i might get an Emporia power monitor that goes in the breaker box after Christmas. It will be great to know what kind of usage and surges i have. only problem is, i dont want to wait a year to collect the data!

NEC allows you to use 30 day data for load calculations as long as you're smart at making extrapolations from that 30 day data to the full year and don't have complications like battery or solar (strict prohibition), so presumably you're smarter than the intelligence level of practitioners that NEC assumes.

Are these trees gone? You might be able to string those 3 small arrays into the same MPPT (they need the same orientation), the disconnect switch at each array might be slightly trickier but probably solvable.

For the pictures with ground mounts property line, you need to check with AHJ on what the property line setback rules are. I don't think those would fly where I am.

Is this property a single meter with the bottom house getting the service drop, and then a feeder already trenched from there to the other house? if so then you could potentially put the backfeed there, and then the other house gets power via AC.

If the bottom house has the service drop, then putting the inverter there gets both houses emergency power. Putting the inverter at the top house may be OK too in this case if that's where you need the emergency power.

If the top house has the service drop, then putting the inverter at the bottom house would only give the bottom house emergency power (unless you do some expensive trenching & find some hardware to allow bottom house to disconnect grid at top house)

Even though wire isnt "cheap" it's not incredibly terrible. so i will run #6 conductors. not sure how many. Maybe 2x as many as required right now. Any reason to run ethernet out there? The trees have been cut down btw.

For those 150 ft lines the incremental cost of more conductors isn't really that much vs trenching in the firstp lace, you can go to 4 circuits without going deep into the derating hole. 80% from 4-6 current carrying conductors, 70% from 7-9 conductors. Ground excluded from current carrying. Spares must be counted as current carrying under current NEC.

If you want to go crazy with spares you need multiple conduits or separate direct bury cables. I feel like 4 should be pretty good.