Back in December I built four seplos mason boxes, with the new v3 bms, they were 200a models, 16s. I was excited to finally have a bms actually capable of active cell balancing.

I connected one up to a single Quattro which was already capacitors charged by a mppt so there was no inrush current. As with all new batteries I backed the current limits down to about 50a and fired it up. All good. Then as I increased the current limit to about 150a and it started to smoke. The smell was of the electronics 'magic smoke' verity. But I was very nervous. Having build hundred of batteries in the last few years, this was the first failure involving potentially a fire.

This is not ideal, by the time I noticed the smoke, I was at 150a and it was really smoking. As a heavy unit this is not something you want to see as its not easy to get out of the building in a rapid pace.

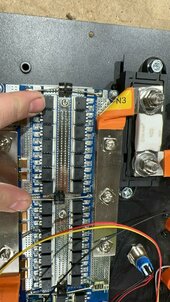

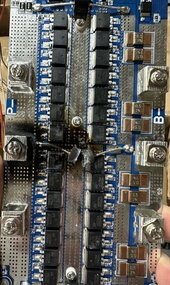

I took the mason box apart and saw the faulty components were cracked, its the components that cross the board between the mosfets. I disconnected the board from the cells with haste.

At this point it was a one off, but I had three more, so I connected up two more masons in parallel this time and did the same test, again, smoke from both batteries when I goto about 80-100a I guess - per battery. Oh dear, this time I knew it was the boards not the cells, so I was in less of a panic, but its still not good. I was not going to try the fourth one. I had to get 20 or so batteries built in December but couldn't continue with the v3. I had no choice but to go back to the v2, so here I am with a three month delay and batteries running on the v2.... But no magic smoke or fire risk...

For those 2-3 months I worried that I had done something wrong, but they were all built well and seplos just said it was my fault, I asked how it was my fault and they said you mush have shorted the bms. Well, this was not the case, I told them it happened not at 50a but at about 150a or some where in-between.

I asked if they had actually tested the new bms's with higher currents, as its a 200a bms you would hope they are testing with over 200a obviously. They didn't answer, so thats a no in my book - I dont think they are testing the bms's any where near the current limits they are designed for.

I busied my self with the v2 bms's and worried all over Christmas and really, until the end of feb when I came across some one else who also had a failed v3, same component, but their board went unnoticed for a period and there must have been a flame of some sort. Now i'm more relieved because it wasn't something I did.

I should have kept on pestering seplos until I had an answer but ive been very busy for the last few months, in the back of my head worrying about these v3s. But now I know its not isolated to me I want to let others know. Be careful at higher currents. In fact, until seplos give us some actual information, I would avoid the v3 entirely. God knows how many v3 are out in the wild getting hot and waiting to catch fire. Its not an isolated incident. Be very careful.

Unfortunately I wanted to swap over to the JK inverter bms, but around Christmas that had its own safety concerns regarding overcharging cells.

Not great. Whats the next stage. Shall I keep pestering seplos, say its not an isolated incident and they need to let all there v3 customers know. Is there a regulator in china for this sort of kit ?

I connected one up to a single Quattro which was already capacitors charged by a mppt so there was no inrush current. As with all new batteries I backed the current limits down to about 50a and fired it up. All good. Then as I increased the current limit to about 150a and it started to smoke. The smell was of the electronics 'magic smoke' verity. But I was very nervous. Having build hundred of batteries in the last few years, this was the first failure involving potentially a fire.

This is not ideal, by the time I noticed the smoke, I was at 150a and it was really smoking. As a heavy unit this is not something you want to see as its not easy to get out of the building in a rapid pace.

I took the mason box apart and saw the faulty components were cracked, its the components that cross the board between the mosfets. I disconnected the board from the cells with haste.

At this point it was a one off, but I had three more, so I connected up two more masons in parallel this time and did the same test, again, smoke from both batteries when I goto about 80-100a I guess - per battery. Oh dear, this time I knew it was the boards not the cells, so I was in less of a panic, but its still not good. I was not going to try the fourth one. I had to get 20 or so batteries built in December but couldn't continue with the v3. I had no choice but to go back to the v2, so here I am with a three month delay and batteries running on the v2.... But no magic smoke or fire risk...

For those 2-3 months I worried that I had done something wrong, but they were all built well and seplos just said it was my fault, I asked how it was my fault and they said you mush have shorted the bms. Well, this was not the case, I told them it happened not at 50a but at about 150a or some where in-between.

I asked if they had actually tested the new bms's with higher currents, as its a 200a bms you would hope they are testing with over 200a obviously. They didn't answer, so thats a no in my book - I dont think they are testing the bms's any where near the current limits they are designed for.

I busied my self with the v2 bms's and worried all over Christmas and really, until the end of feb when I came across some one else who also had a failed v3, same component, but their board went unnoticed for a period and there must have been a flame of some sort. Now i'm more relieved because it wasn't something I did.

I should have kept on pestering seplos until I had an answer but ive been very busy for the last few months, in the back of my head worrying about these v3s. But now I know its not isolated to me I want to let others know. Be careful at higher currents. In fact, until seplos give us some actual information, I would avoid the v3 entirely. God knows how many v3 are out in the wild getting hot and waiting to catch fire. Its not an isolated incident. Be very careful.

Unfortunately I wanted to swap over to the JK inverter bms, but around Christmas that had its own safety concerns regarding overcharging cells.

Not great. Whats the next stage. Shall I keep pestering seplos, say its not an isolated incident and they need to let all there v3 customers know. Is there a regulator in china for this sort of kit ?

Attachments

Last edited: