Last update 3/31, last post

This will be a work in process as I figure out the ins and outs of this methodology. Apologies if images are not visible to some, I am still learning.

This is phase I of a two phase project. The first part of the project included building what amounts to a UPS.

At the top of the photo you will see yellow and orange wire.

The orange is 10 gauge wire and runs from a dedicated subpanel with a shut off. Per forum instructions the neutral and ground are separate. This is the ac input and the voltage input will be adjusted accordingly in the Multiplus software.

The yellow wires are 12 gauge and run to a total of three dedicated outlets separate from the home which can be used for lighting, etc.

The ac box, while it shows three breakers, only has two 15 amp breakers active at this time. Again, the ground and neutral are separate.

It is hard to estimate the number of hours dedicated to the components below.

The back wall is a number of 2/4s vertically attached to wall studs and running to the concrete floor. At the top are 2 cross beams of 2x10 which create a very firm attachment point for the Victron inverter charger. I hope to post photos later on this. The framework is then covered and attached to 3/4 inch plywood. The plywood was then painted with a fire resistant/proof paint prior to be being covered by hardiboard.

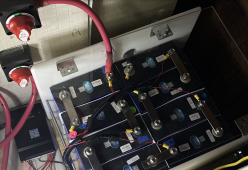

The batteries are two 24 volt units consisting of 8 CATL 302 amp cells. Each is attached to a separate Overkill BMS in the back. The sides are heavy duty vinyl. The top is 1/4 inch polycarbonate for protecting the packs. Between the batteries and under each is hardiboard. The cells have been insulated from each other to reduce possible cell leakage. At the positive terminal, a custom 90 degree pure copper bus bar has been placed which then feeds an attachment terminal on the side. While you see threaded rods on the sides, I elected not to utilize compression. The nuts on the ends are finger tightened only to allow a comfortable place for the batteries to rest.

The cart underneath is on 4 independent rollers and allows one to roll the batteries out of the storage area if any maintenance is needed.

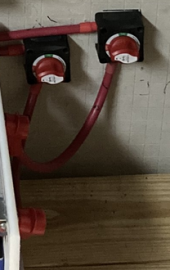

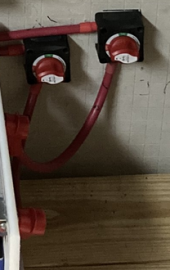

The wiring for each battery runs to a dedicated shut off switch which were placed to permit maintenance if needed.

The batteries run to a Vicron Distributor which has fusing built in. Since it acts basically as a fancy bus bar, it helps to make sure that input and output from attached batteries both receive and distribute power evenly.

The negative terminal from the distributor runs to a Vicron Smart Shunt before attaching to a Victron 600 amp bus bar.

The positive terminal from the distributor also attaches to its own bus bar.

The bus bars are there in case 12v current is wanted in the future and to allow a future attachment point for the solar input which is scheduled for this year.

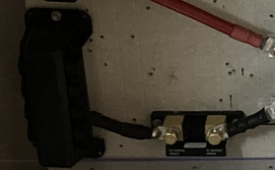

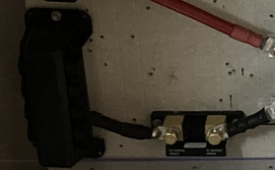

The positive bus bar runs to a master shut off switch before running to a breaker.

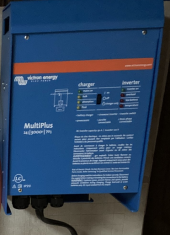

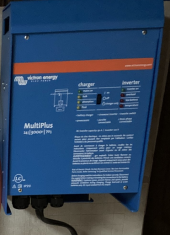

Not pictured is the charge controller (still in box) and the positive and negative lines to the inverter charger, which is the Victron 24v Multiplus system. This one is UL rated.

The wire from each battery is 1/0. Everything from the distributor on is 2/0. If I were working with 12v then these would be double thickness.

Most of the lugs are Selterm brand. The individual components are from Blue Sea and Victron.

This will be a work in process as I figure out the ins and outs of this methodology. Apologies if images are not visible to some, I am still learning.

This is phase I of a two phase project. The first part of the project included building what amounts to a UPS.

At the top of the photo you will see yellow and orange wire.

The orange is 10 gauge wire and runs from a dedicated subpanel with a shut off. Per forum instructions the neutral and ground are separate. This is the ac input and the voltage input will be adjusted accordingly in the Multiplus software.

The yellow wires are 12 gauge and run to a total of three dedicated outlets separate from the home which can be used for lighting, etc.

The ac box, while it shows three breakers, only has two 15 amp breakers active at this time. Again, the ground and neutral are separate.

It is hard to estimate the number of hours dedicated to the components below.

The back wall is a number of 2/4s vertically attached to wall studs and running to the concrete floor. At the top are 2 cross beams of 2x10 which create a very firm attachment point for the Victron inverter charger. I hope to post photos later on this. The framework is then covered and attached to 3/4 inch plywood. The plywood was then painted with a fire resistant/proof paint prior to be being covered by hardiboard.

The batteries are two 24 volt units consisting of 8 CATL 302 amp cells. Each is attached to a separate Overkill BMS in the back. The sides are heavy duty vinyl. The top is 1/4 inch polycarbonate for protecting the packs. Between the batteries and under each is hardiboard. The cells have been insulated from each other to reduce possible cell leakage. At the positive terminal, a custom 90 degree pure copper bus bar has been placed which then feeds an attachment terminal on the side. While you see threaded rods on the sides, I elected not to utilize compression. The nuts on the ends are finger tightened only to allow a comfortable place for the batteries to rest.

The cart underneath is on 4 independent rollers and allows one to roll the batteries out of the storage area if any maintenance is needed.

The wiring for each battery runs to a dedicated shut off switch which were placed to permit maintenance if needed.

The batteries run to a Vicron Distributor which has fusing built in. Since it acts basically as a fancy bus bar, it helps to make sure that input and output from attached batteries both receive and distribute power evenly.

The negative terminal from the distributor runs to a Vicron Smart Shunt before attaching to a Victron 600 amp bus bar.

The positive terminal from the distributor also attaches to its own bus bar.

The bus bars are there in case 12v current is wanted in the future and to allow a future attachment point for the solar input which is scheduled for this year.

The positive bus bar runs to a master shut off switch before running to a breaker.

Not pictured is the charge controller (still in box) and the positive and negative lines to the inverter charger, which is the Victron 24v Multiplus system. This one is UL rated.

The wire from each battery is 1/0. Everything from the distributor on is 2/0. If I were working with 12v then these would be double thickness.

Most of the lugs are Selterm brand. The individual components are from Blue Sea and Victron.

Last edited: