If not desiring to mount Solar panels on a roof, (which I don't prefer for many reasons...especially with bifacials) racking can be one of the most expensive parts of the system. Most really don't allow much flexibility or adaptability let alone mobility...definitely not cheaply in time, labor or money.

So...I started with an old cheap but completely functional 17' single axle boat trailer for $300 as a foundation. For a financial & weight penalty one could easily substitute a tandem but I didn't feel it was needed for my application or goals. I then added a used DC Solar racking system that I picked up reasonably for about the same price as the raw steel. I could have easily built similar but this was faster & much less labor. I actually believe it was cheaper financially even DIY.

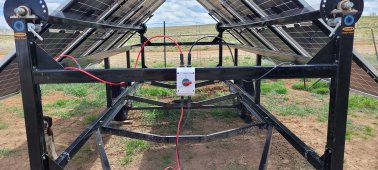

With the help of a great friend, I then attached it compete with the great but simple pillow block bearing pivoting system. I designed this to be removable with 6 large bolts but with permanent welded brackets. As it orginally had smaller, weaker & very dated 5x2=10 mono panels (previously removed), I relocated & reinforced the orginal bracket geometry in favor of 4-3.5'x7' bifacial panels on each side for a total of 8 for +3,120w. Panels sit plenty high to take advantage of their full bifacial capabilities & out of the snow & provide drainage. (Which I've clocked higher than 500w per for short periods but 450w for longer periods.) They are obviously easy to clean & maintain.

Basically, I set it up as TWO arrays that can be connected in series or parallel or individually. Even being 3.5'x7' panels, the way we mounted each side, it does NOT shadow each other no matter the time of day...so far. (Winter solstice may be slight?) Each side individually pivots 270 degrees...can be 100% horizontal but also 100% vertical for transport. (with locked double 1/2" pins on each side. It can be parked anywhere as the panels can pivot to what ever side is south etc. It also has tethering points on all 4 corners for anchoring.

Basically, it is meant to be a +3.2 KW portable power generation system based on the the old DC Solar designs intentionally sans the batteries & inverters etc. This was meant to be portable as well & interchangeable depending what components you want to use with it with the click of 2 cables...NOT onboard, although they could be added if desired. (DC Solar's HEAVY forklift batteries, though, dictated way too much to the platform & too little flexibility.) I can use a side by side to easily move this around.

Currently use is a single EG4 inverter & 4 EG4 batteries stored in an insulated & vented storage container with a 50 amp plug for our 5th Wheel & additional outlets...50' away. I.E. 2 simple 8 awg extension cables. Later it will be moved to our house for use while living in & finishing it. (Post frame) It will then eventually be replaced with a permanent array. Later again to a barn & or AirBnB cabins etc. It works for me & the cost & flexibility is right.

So...I started with an old cheap but completely functional 17' single axle boat trailer for $300 as a foundation. For a financial & weight penalty one could easily substitute a tandem but I didn't feel it was needed for my application or goals. I then added a used DC Solar racking system that I picked up reasonably for about the same price as the raw steel. I could have easily built similar but this was faster & much less labor. I actually believe it was cheaper financially even DIY.

With the help of a great friend, I then attached it compete with the great but simple pillow block bearing pivoting system. I designed this to be removable with 6 large bolts but with permanent welded brackets. As it orginally had smaller, weaker & very dated 5x2=10 mono panels (previously removed), I relocated & reinforced the orginal bracket geometry in favor of 4-3.5'x7' bifacial panels on each side for a total of 8 for +3,120w. Panels sit plenty high to take advantage of their full bifacial capabilities & out of the snow & provide drainage. (Which I've clocked higher than 500w per for short periods but 450w for longer periods.) They are obviously easy to clean & maintain.

Basically, I set it up as TWO arrays that can be connected in series or parallel or individually. Even being 3.5'x7' panels, the way we mounted each side, it does NOT shadow each other no matter the time of day...so far. (Winter solstice may be slight?) Each side individually pivots 270 degrees...can be 100% horizontal but also 100% vertical for transport. (with locked double 1/2" pins on each side. It can be parked anywhere as the panels can pivot to what ever side is south etc. It also has tethering points on all 4 corners for anchoring.

Basically, it is meant to be a +3.2 KW portable power generation system based on the the old DC Solar designs intentionally sans the batteries & inverters etc. This was meant to be portable as well & interchangeable depending what components you want to use with it with the click of 2 cables...NOT onboard, although they could be added if desired. (DC Solar's HEAVY forklift batteries, though, dictated way too much to the platform & too little flexibility.) I can use a side by side to easily move this around.

Currently use is a single EG4 inverter & 4 EG4 batteries stored in an insulated & vented storage container with a 50 amp plug for our 5th Wheel & additional outlets...50' away. I.E. 2 simple 8 awg extension cables. Later it will be moved to our house for use while living in & finishing it. (Post frame) It will then eventually be replaced with a permanent array. Later again to a barn & or AirBnB cabins etc. It works for me & the cost & flexibility is right.

Attachments

-

20230417_112142.jpg452.3 KB · Views: 63

20230417_112142.jpg452.3 KB · Views: 63 -

20230417_112335.jpg597.5 KB · Views: 157

20230417_112335.jpg597.5 KB · Views: 157 -

20230417_112323.jpg613.4 KB · Views: 58

20230417_112323.jpg613.4 KB · Views: 58 -

20230417_112311.jpg633.4 KB · Views: 56

20230417_112311.jpg633.4 KB · Views: 56 -

20230417_112255.jpg565.9 KB · Views: 55

20230417_112255.jpg565.9 KB · Views: 55 -

20230417_112247.jpg564.1 KB · Views: 53

20230417_112247.jpg564.1 KB · Views: 53 -

20230417_112224.jpg529.3 KB · Views: 51

20230417_112224.jpg529.3 KB · Views: 51 -

20230417_112212.jpg476.2 KB · Views: 47

20230417_112212.jpg476.2 KB · Views: 47 -

20230417_112203.jpg473.2 KB · Views: 47

20230417_112203.jpg473.2 KB · Views: 47 -

20230417_112152.jpg449.6 KB · Views: 60

20230417_112152.jpg449.6 KB · Views: 60