Westcliffe01

New Member

I finally closed on a land parcel in Custer County CO. 36 acres at 9000ft in the wet mountains. The >1000 acre subdivision has no utilities, like many in the area. Long term water will be from a 300-500ft deep well, but given the approximately $26k+ cost of drilling the well, that will have to wait for a later date. There is a fair amount of building going on in the area compared to 10 years ago, but the majority of that effort is on multi million $ homes up on the ridge parcels. Local builders are asking $400/sqft.

So I have made the choice to build myself and cease my employment until I have taken care of the shelter situation. Trees do not grow in the area of the site, so shading issues are under my control. The valley runs close to a N/S direction so good solar exposure even in winter. Sunrise and sunset will be later and earlier respectively due to the Wet mountains in the east and Sangres range to the west @11k and 12+k feet high respectively so 3000+ ft higher than my site.

This picture from the western side of the Valley, where the Sangres were glaciated in the past.

I have a 6kW diesel generator, and previously purchased a 1.65kW PV array. The panels have a 39V OC voltage, 275W each and I have a midnight 200 classic charge controller. Because of the high voltage I would hit the voltage limit on the Midnite by 5 units and since I have 6, it makes sense to put 2 strings in series 3 each and 2 in parallel. That would put the PV voltage at 117V and in the sunny cold (frequent) conditions it will probably be higher. But plenty of voltage margin for the charge controller given the 3s 2p configuration. For the inverter, I have elected to go with a Sungoldpower 4kW 24V split phase low frequency inverter. For batteries I went with 4x 25.6v 75ah 1.92kWh Lifepo4 batteries which will be connected in parallel.

The above is intended to carry me through the build phase of the project. The main load on the PV system on a 24/7 basis will be running a DC refrigerator which has a maximum draw of about 150W but cycles on and off based on the thermostat. The refrigerator and DC lighting in my "survival shack" will operate off 24V without the inverter needing to be active. During the day I will need to charge tool batteries (18V Ryobi battery system) as well as run AC tools like the table saw or my 5hp single phase 240V compressor. The compressor would not need to cycle frequently so long as I maintain the hose quick couplings to eliminate leaks. During particularly busy times, if needed I will run the diesel generator to support loads and maintain battery charge. Generally, the PV array should be able to maintain a decent inflow to keep the lithium batteries charged and especially in the afternoons there should be excess solar power. I have more or less matched the inverter to the size of the genset and the good load starting characteristics of the inverter should be more than adequate for any tool that I possess.

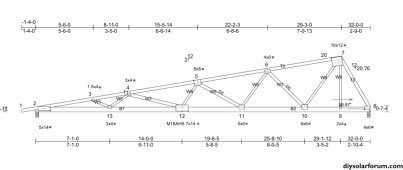

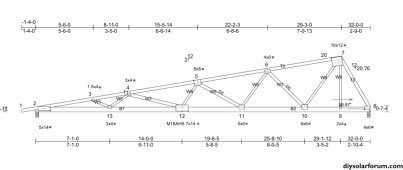

The first structure that I will be building is a 32x40 "garage" shell (what Menards calls it) onto which I will put a shed style roof, modified on the southern side by having a short steep slope as pictured below, which will form the mounting surface for the expanded solar array. Shown on the right side of the truss in the picture below. The building is 40' long with 2' overhangs on each end so a total length for mounting the solar panels of 44'. My 6x current panels are 40" wide so 20' of that surface is already allocated which suggests that the size of the array can be doubled without looking for additional space to fit more. Given that the area is a free range cattle grazing area, until such time I put an appropriate fence up, I need to be sure that nothing can be reached by the horns of the cattle nor stepped on. That would be why I am not considering a ground mount. The steep angle is also to maximise winter performance and assist snow in sliding off. There should not be any need for me to get on the roof or use a ladder to access the panels. I could consider making the panel attachment pivot at the top and moveable at the bottom so that the angle can be reduced in summer but I may want to weather a few seasons first since the area is known for 120mph wind storms so everything has to be super robust.

Once the home is built I will get started on the shop which is going to be 40x60 with 12' ceilings, so a much larger building. The roof would be too high to make PV maintenance feasible, so I will give some thought to how to expand the PV array on that building. The shop is where the most power would be consumed, so its logical that the bulk of the PV array should be close. I may align the axis of the building N/S and build a false roof with a short overhang on the southern side at a suitable height to mount the PV array on. For the shop I was considering building my own battery with the highest voltage compatible with a split phase inverter for 240V. Id like to go with 96V or even more, but it depends on whether I can get a suitable inverter. Many of the tools in the shop will be 240V so it would seem that efficiency would be higher if battery bank voltage was higher too. It would reduce the amount of expensive heavy copper wire needed. It would mean I could run more PV panels in series and go with a solar charge controller that has a high input voltage. So far I am only aware of the Sigineer inverter that accepts 96V on the input Link

My existing battery could be re-configured to a 96V configuration by connecting the 4 batteries in series instead of parallel. I could ultimately use the 4kW 24V inverter as a dedicated power supply for the well. I do not yet have any idea where the well will end up being drilled based on the local geology. Usually one can expect to not have a well with a high flow rate, thus a smaller pump flowing into a cistern that is underground to act as a buffer is the best solution and also fits into county fire protection plans so that one has adequate water on hand to fight grass fires without waiting on the volunteer fire department.

Long post, perhaps some more experienced members can point out the flaws in my logic. Thank you

So I have made the choice to build myself and cease my employment until I have taken care of the shelter situation. Trees do not grow in the area of the site, so shading issues are under my control. The valley runs close to a N/S direction so good solar exposure even in winter. Sunrise and sunset will be later and earlier respectively due to the Wet mountains in the east and Sangres range to the west @11k and 12+k feet high respectively so 3000+ ft higher than my site.

This picture from the western side of the Valley, where the Sangres were glaciated in the past.

I have a 6kW diesel generator, and previously purchased a 1.65kW PV array. The panels have a 39V OC voltage, 275W each and I have a midnight 200 classic charge controller. Because of the high voltage I would hit the voltage limit on the Midnite by 5 units and since I have 6, it makes sense to put 2 strings in series 3 each and 2 in parallel. That would put the PV voltage at 117V and in the sunny cold (frequent) conditions it will probably be higher. But plenty of voltage margin for the charge controller given the 3s 2p configuration. For the inverter, I have elected to go with a Sungoldpower 4kW 24V split phase low frequency inverter. For batteries I went with 4x 25.6v 75ah 1.92kWh Lifepo4 batteries which will be connected in parallel.

The above is intended to carry me through the build phase of the project. The main load on the PV system on a 24/7 basis will be running a DC refrigerator which has a maximum draw of about 150W but cycles on and off based on the thermostat. The refrigerator and DC lighting in my "survival shack" will operate off 24V without the inverter needing to be active. During the day I will need to charge tool batteries (18V Ryobi battery system) as well as run AC tools like the table saw or my 5hp single phase 240V compressor. The compressor would not need to cycle frequently so long as I maintain the hose quick couplings to eliminate leaks. During particularly busy times, if needed I will run the diesel generator to support loads and maintain battery charge. Generally, the PV array should be able to maintain a decent inflow to keep the lithium batteries charged and especially in the afternoons there should be excess solar power. I have more or less matched the inverter to the size of the genset and the good load starting characteristics of the inverter should be more than adequate for any tool that I possess.

The first structure that I will be building is a 32x40 "garage" shell (what Menards calls it) onto which I will put a shed style roof, modified on the southern side by having a short steep slope as pictured below, which will form the mounting surface for the expanded solar array. Shown on the right side of the truss in the picture below. The building is 40' long with 2' overhangs on each end so a total length for mounting the solar panels of 44'. My 6x current panels are 40" wide so 20' of that surface is already allocated which suggests that the size of the array can be doubled without looking for additional space to fit more. Given that the area is a free range cattle grazing area, until such time I put an appropriate fence up, I need to be sure that nothing can be reached by the horns of the cattle nor stepped on. That would be why I am not considering a ground mount. The steep angle is also to maximise winter performance and assist snow in sliding off. There should not be any need for me to get on the roof or use a ladder to access the panels. I could consider making the panel attachment pivot at the top and moveable at the bottom so that the angle can be reduced in summer but I may want to weather a few seasons first since the area is known for 120mph wind storms so everything has to be super robust.

Once the home is built I will get started on the shop which is going to be 40x60 with 12' ceilings, so a much larger building. The roof would be too high to make PV maintenance feasible, so I will give some thought to how to expand the PV array on that building. The shop is where the most power would be consumed, so its logical that the bulk of the PV array should be close. I may align the axis of the building N/S and build a false roof with a short overhang on the southern side at a suitable height to mount the PV array on. For the shop I was considering building my own battery with the highest voltage compatible with a split phase inverter for 240V. Id like to go with 96V or even more, but it depends on whether I can get a suitable inverter. Many of the tools in the shop will be 240V so it would seem that efficiency would be higher if battery bank voltage was higher too. It would reduce the amount of expensive heavy copper wire needed. It would mean I could run more PV panels in series and go with a solar charge controller that has a high input voltage. So far I am only aware of the Sigineer inverter that accepts 96V on the input Link

My existing battery could be re-configured to a 96V configuration by connecting the 4 batteries in series instead of parallel. I could ultimately use the 4kW 24V inverter as a dedicated power supply for the well. I do not yet have any idea where the well will end up being drilled based on the local geology. Usually one can expect to not have a well with a high flow rate, thus a smaller pump flowing into a cistern that is underground to act as a buffer is the best solution and also fits into county fire protection plans so that one has adequate water on hand to fight grass fires without waiting on the volunteer fire department.

Long post, perhaps some more experienced members can point out the flaws in my logic. Thank you