I think I done messed up….

( Note: I can’t physically put anything together until after my building inspection)

I’m buying and laying out everything for an upcoming install. Got the Sol-Ark 15k, got the Iron Ridge mounting, the panels I was going to buy went away (out of stock forever).

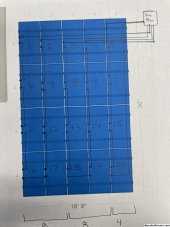

I came across some JA 535W Panels for less than $200 per panel. I panicked and bought 20 (the max I have space to mount). Now they are on their way and I remember I should work out wiring….

Per Sol Ark online string calculator I can handle 9 MAX on input 1, and 9 MAX on input 2. I CANNOT handle only 2 on input 3- I assume due to minimal voltage.

Question 1: So shit now what? Any way I can make these extra two work?

Question 2: my rows are 5 panels each which is going to make wiring awkward with 9 panels. Any suggestions to help? Branch connectors? I’m going to be using an iron ridge jay box- maybe combine them in there and just eat the cost on extra wire?

Got a great deal on panels (I think) but caused other issues.

Thanks

( Note: I can’t physically put anything together until after my building inspection)

I’m buying and laying out everything for an upcoming install. Got the Sol-Ark 15k, got the Iron Ridge mounting, the panels I was going to buy went away (out of stock forever).

I came across some JA 535W Panels for less than $200 per panel. I panicked and bought 20 (the max I have space to mount). Now they are on their way and I remember I should work out wiring….

Per Sol Ark online string calculator I can handle 9 MAX on input 1, and 9 MAX on input 2. I CANNOT handle only 2 on input 3- I assume due to minimal voltage.

Question 1: So shit now what? Any way I can make these extra two work?

Question 2: my rows are 5 panels each which is going to make wiring awkward with 9 panels. Any suggestions to help? Branch connectors? I’m going to be using an iron ridge jay box- maybe combine them in there and just eat the cost on extra wire?

Got a great deal on panels (I think) but caused other issues.

Thanks