silverstone

Solar Enthusiast

- Joined

- May 3, 2022

- Messages

- 1,041

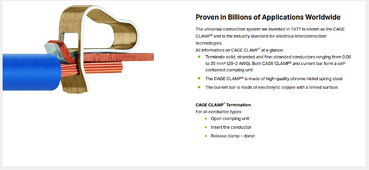

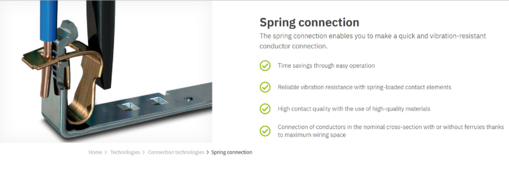

I hope I don't have to rework all that I've done until now since I twisted them somewhatThe 285-150 is a much different design. It requires an operating tool to insert and remove the wire. No ferrule is needed. The reason you should not twist the wires is the number of strands that contact the clamping point will be less resulting in more heat being generated at the contact point. If you remove the wire, you will notice the strands are flared out like an artist's paint brush. It won't do this well if you twist them too tightly.

But you think the WAGO 285-150 won't crush the Class 6 conductor ? I mean these JK BMS Class 6 strands are like 10-20 times SMALLER than a human hair ...

I can follow you with e.g. 50mm2 Class 5 ... those are still relatively big individual strands and should surive mechanically.