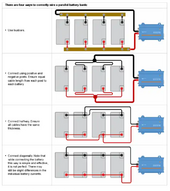

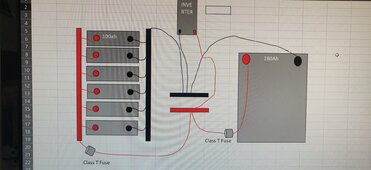

So, I have an 18kvp, a powerpro 280ah battery, and 6 Lifepower4 100ah batteries. I have an EG4 rack for the six LP4 batteries. However according to EG4 hooking a bank of six LP4 to the system will create "sever" balancing issues. So I have to have banks of 3, but I don't want to purchase another 6 slot rack and have two half empty racks taking up twice the floor space. And I don't want to drop another $3500+ on another wall mount battery to balance things out.

So my question is, can I just cut the busbars in the rack in half and have two banks of three in one rack? Will this pass code, and if not, does it cause any safety issues? How large a gap do I need between the two busbars so there is no arcing?

Thanks!

So my question is, can I just cut the busbars in the rack in half and have two banks of three in one rack? Will this pass code, and if not, does it cause any safety issues? How large a gap do I need between the two busbars so there is no arcing?

Thanks!