Kcdaniels

New Member

- Joined

- Sep 22, 2019

- Messages

- 263

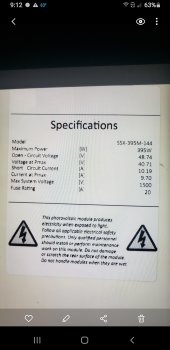

I'm A little confused...? Is there a way this will work or would I have to go to 24 volt setup as now I'm 12 volt ? I have two of these 395 watt panels..

Victron says max 700 watts for the 100/50

Victron says max 700 watts for the 100/50