consolelog

New Member

- Joined

- Jun 8, 2020

- Messages

- 10

Hey all, I'm finally getting around to diving into this issue.

I have a 180amp alternator, connected to 2 Orion 12/12-30 non-isolated chargers to charge my 2x 270AH Lithium house batteries. Whenever the chargers kick in, I can see on the app the voltage input of the Orions drop from ~14V down to 11V, cutting the charging off. The truck's starter battery voltage does not drop when this happens. I've also tried to connect just one Orion, but it still occurs.

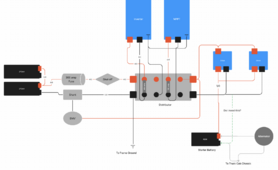

The positive from the starter battery to the Orions is ~10ft at 1/0 (I have them branched+fused to 6AWG so they can fit into the Orion ports). The ground is connected to a distributor, which is grounded with a 4/0 wire directly to the truck's frame (not cab chassis).

I'm thinking this could be an issue with the ground? This is on a truck camper, where the starter battery + alternator are grounded to the truck's cab chassis. On my house batteries, I've grounded it by tapping directly to the truck's frame. Are these grounds actually different, and the truck's body mounts don't provide enough connections between the frame and chassis?

If so, is it safe to run an additional ground from the starter battery, to a junction that connects the Orions + house distributor? (Green dashed line in my diagram). This would essentially connect the frame ground to the chassis ground

TIA

I have a 180amp alternator, connected to 2 Orion 12/12-30 non-isolated chargers to charge my 2x 270AH Lithium house batteries. Whenever the chargers kick in, I can see on the app the voltage input of the Orions drop from ~14V down to 11V, cutting the charging off. The truck's starter battery voltage does not drop when this happens. I've also tried to connect just one Orion, but it still occurs.

The positive from the starter battery to the Orions is ~10ft at 1/0 (I have them branched+fused to 6AWG so they can fit into the Orion ports). The ground is connected to a distributor, which is grounded with a 4/0 wire directly to the truck's frame (not cab chassis).

I'm thinking this could be an issue with the ground? This is on a truck camper, where the starter battery + alternator are grounded to the truck's cab chassis. On my house batteries, I've grounded it by tapping directly to the truck's frame. Are these grounds actually different, and the truck's body mounts don't provide enough connections between the frame and chassis?

If so, is it safe to run an additional ground from the starter battery, to a junction that connects the Orions + house distributor? (Green dashed line in my diagram). This would essentially connect the frame ground to the chassis ground

TIA