Hello all you creative inventors out there..

I have this remote cabin with 800w solar and a 24v/230v/3000w inverter. kind of a modern setup in a small cabin far into the woods.. in february to september its no problem, plenty of Solar/battery power. But in the darkest wintermonths there is like no solar charging. I have a predator 3500i generator for charging. no problem..

But, I like to do some mechanics and make stuff, so I`w been thinking..;

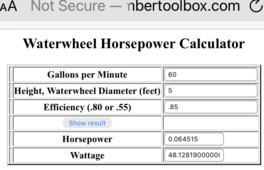

There`s a small stream nearby the cabin, there i have made a Watermill with my kids, just for fun.

What if i make a small water generator to charge the batteries while I `m at the cabin in the dark season! THen i dont have to start the generator!

At daytime I have a average of 150-200w/h at 230v ( displayed from the victron smartshunt).

If I can charge the batteries with 100w 24/7 it will be enough for the whole week! At nighttime here`s almost no power consuption, so 100w in will be enough i think.

Why so small? Just so its easier to control if something goes wrong, I will of course have fuses all over..

Just to be on the safe side..

I can mount a 12v car alternator on the watermill, then to a12v car battery, then to a 12v/230v inverter then to a 230v/24v carger that charges the battery with like 100w/24v/8A .

its like 80m from the cabin, so its a bit long to transport DC power to the battery, therefore I think having a 12/230v inverter at the alternator , its better to send 230v thru a cable 80m long. .

THen when i leave the cabin i turn the whole thing off. cant let the watermill go the rest of the winter unintended..

any of you with experience with alternators? do I need a car chargecontroller for it? or maybe it will be good enough with a Victron DC-DC 12-12?

other ideas?

I have this remote cabin with 800w solar and a 24v/230v/3000w inverter. kind of a modern setup in a small cabin far into the woods.. in february to september its no problem, plenty of Solar/battery power. But in the darkest wintermonths there is like no solar charging. I have a predator 3500i generator for charging. no problem..

But, I like to do some mechanics and make stuff, so I`w been thinking..;

There`s a small stream nearby the cabin, there i have made a Watermill with my kids, just for fun.

What if i make a small water generator to charge the batteries while I `m at the cabin in the dark season! THen i dont have to start the generator!

At daytime I have a average of 150-200w/h at 230v ( displayed from the victron smartshunt).

If I can charge the batteries with 100w 24/7 it will be enough for the whole week! At nighttime here`s almost no power consuption, so 100w in will be enough i think.

Why so small? Just so its easier to control if something goes wrong, I will of course have fuses all over..

Just to be on the safe side..

I can mount a 12v car alternator on the watermill, then to a12v car battery, then to a 12v/230v inverter then to a 230v/24v carger that charges the battery with like 100w/24v/8A .

its like 80m from the cabin, so its a bit long to transport DC power to the battery, therefore I think having a 12/230v inverter at the alternator , its better to send 230v thru a cable 80m long. .

THen when i leave the cabin i turn the whole thing off. cant let the watermill go the rest of the winter unintended..

any of you with experience with alternators? do I need a car chargecontroller for it? or maybe it will be good enough with a Victron DC-DC 12-12?

other ideas?