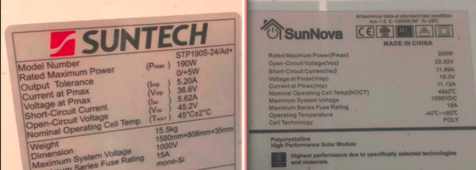

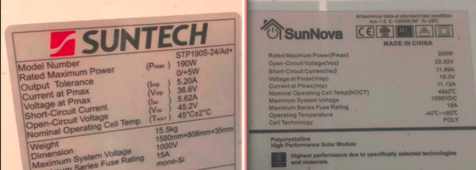

Check the panels for their recommended fuse rating for that '10A' fuse (most 190w panels have a 15A or higher recommended fuse, depending on the exact panel specs (Isc etc)- its usually written on the label on the back of the panel

The panels breaker would be that fuse rating x2 (and located at the victron, not the panels as suggested by your diagram)

Your 300A fuse at the inverter is pretty low- its ok, but you may need to 'precharge' the inverter when connecting or if high surge currents if it is loaded right to its max anytime in the future- a 3kw HF inverter could sustain peaks of up to 6kw for about half a second, a LF 3kw peaks of up to 9kw for up to 20 seconds... (your Kings 3kw is a HF btw so a 6kw 'peak' for up to half a second during which that fuse could see over 500A...)

(precharging is where you use a current limited supply to precharge the inverters filter capacitors before connecting to the main battery supply, it becomes important when you step up to the 10kw and higher range, but with your fuse only rated at 300A, you are at the lower end of what would be acceptable for a 3kw inverter)

The wiring doesn't need to be 1000v stuff, the 600v cable is quite ok (indeed many gridtie systems use standard '240v mains' TPE in Australia (which has a 600v rating- but it does have to be run in PVC conduit as it isn't UV stabilised) as the panels on a gridtie need to need to be earthed , so the TPE's earth cable comes in handy for that). An offgrid system- well there's no 'legal' requirement to run an earth (offgrid is pretty much open slather lol- there are regs, but literally almost no enforcement on them here), but earthing the panels frames is a good idea anyway- it can dissipate static buildup in thunderstorms, which can damage the charge controllers input circuitry... TPE is the standard 'building cable' run in the walls to powerpoints, and standard 2.5mm TPE will be perfect for your array size as long as the run is under 25m- or just use standard PV cables (3mm or 4mm are the most common size and fine)

The starter' cables are 'slightly' oversized for the job (not a bad thing, means less voltage drop in the cables)- but they are cheap and already come with lugs precrimped (a proper crimper to 'diy' can be pretty pricey) and are available in 'lug to lug' or 'lug to battery terminal'

Supercheap Auto (cheapest)

Repco (a bit more expensive), and even Bunnings stock some cables (although their range is quite limited and not all stores carry them in stock) Autobarn also have a reasonable range, but aren't as common as the other three