agree - very strange. Have you checked if one terminal of the cell is getting warmer/hotter than the others?

Also checked torque?

No. No.

It was torqued properly with a Wrench and digital Torque scale/indicator, so torque value should be fine. That was done approx 6 months ago.

And I doubt I'd see anything at 10a-20a near the top of the curve. There just aren't *that* many losses at such low current.

Torque wise, one thing that made me unhappy was that the studs were quite short, so I could only use the busbar + the provided flange nuts, not the proper flat washer + conical washer + nut as I would normally otherwise.

EDIT 1:

Not sure how much that translates into capacity difference between cells. Maybe it's only 1Ah maybe 5Ah (0.3%-2%) ...

But battery 01 definitively behaves much more consistently.

Battery 02 was unbalanced from the very start (cell 01 or 16 was on much lower voltage at the beginning, since it came from an older batch, since the original was leaking electrolyte and had to throw it away), but properly slowly ramped up the voltage 0.1V on the whole pack little by little over 36 hours. Then all cells were at 3.6V (back when I had the OVP set to 3.60V / 3.65V).

That was described in my other thread here:

https://diysolarforum.com/threads/j...d-also-current-power-measurement.79913/page-3 (you can see a bit the voltage evolution, current was very small, but not in those pictures I believe)

You can see how battery 01 has all cells rising together, while battery 02 had some strange push-pull-pull back-push going on, even though it ultimately converges.

At first I thought it was BMS leads wrongly connected, but that would result in instability, not (although slowly) convergence. What was even more surprising was that one cell (turquoise ?) is the first to rise, then goes down a lot, then it's the last to come back ...

This was me raising the voltage 0.1V by 0.1V approx at a rate of 0.1V/hour pr 0.1V/2 hours using a programmable charger (Emerson / Vertiv R48).

But I believe part of the problem is that while the balancer discharges the highest cell, the charger recharges it, that's why it takes SO MUCH LONGER than if the charger (or inverter voltage) would just "back off a little". In that case, as stated in this thread here, I got from 3.55VDC to 3.42VDC in like 180 seconds only (charging disabled from BMS). Lowering the Charger voltage below pack voltage would effectively do the same thing (if PV is sufficient, battery will NOT be discharged).

EDIT 2:

@MrPablo: this is also related to what I was telling you before. It's NOT actually only the tolerances (on BMS and on Inverter) about the voltage measurement, it's also the fact that the voltage needs to be lower in order to give some headroom for the balancer to work without getting counter-acted by the Charger/Inverter.

Because say you are at 54.4 VDC on the Battery Pack (reported by BMS and measured with a multimeter) and 54.4 VDC on the Inverter/Charger (reported by Inverter/Charger and measured with a multimeter). As soon as the JK BMS will start discharging the highest voltage cell, the Inverter/Charger will recharge the pack, based on (54.4 VDC - delta_v_absorbed_by_balancer - 54.4 VDC) / ESR = - delta_v_absorbed_by_balancer / 0.005 Ohm or so ...

So while the JK BMS discharges the highest cell and before it recharges the lowest, you need to ensure that the Charger/Inverter voltage is AT LEAST delta_v_absorbed_by_balancer below the pack voltage. For every cycle of balance effectively ... You can probably calculate this dynamically based on the JK BMS supercapacitor capacitance value and battery capacity and voltage status. Otherwise you kinda get a capacitor multiplier / charge pump going on there (or a "very small" boost converter effectively, discharge highest cell, Inverter/Charge recharges it, JK recharges lowest cell).

EDIT 3:

And I am not so sure that the "Current Charge Control" of 0A works effectively. Again, tolerance measurements here as well on the Inverter Side (0A is very small compared to 240A nominal, so measurement offset / error can be significant with respect to "real" 0A). I set my parameters to Current Curve Factor 1 - End of Curve = 4.00 and Current Curve Factor 1 - Curve Shape = 1.80. It needs to be quite aggressive, in my case at least.

EDIT 4: On Battery 02, it could also be a case of "Balancer Induced Unbalance". Battery 02 was reporting approx. 0.7V HIGHER on pack/battery level (NOT a diode

) than Battery 01 or the Multimeter (again on pack/battery level, i.e. 16 cells !). Battery 01 was also off by 0.1V (again on pack/battery level, i.e. 16 cells !), but nowhere Battery 02.

So you could say that it effectively started balancing at 3.45V - (0.7V/16 cells) = 3.406 V / cell. Well below the charge knee curve. So it probably created quite a bit of unbalance. I have since then calibrated the voltage reading (at NO LOAD !) and also lowered the OVP and OVPR values, since now the safety margin became smaller. But IIRC I have not "top balanced" the system after the voltage offset calibration (you can see in the attached picture there is still approx 0.05V / cell difference between Battery 01 and Battery 02).

EDIT 5:

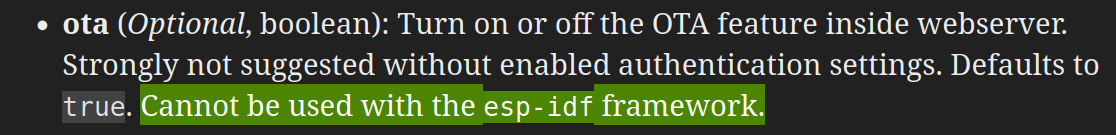

@MrPablo Maybe I can just set this to a NEGATIVE value, so that when Charge voltage is getting reduced by the ESP32, then the inverter will in effect stay a bit LOWER than the battery pack

# Inverter offset, allows you to correct the inverter charging voltage

inverter_offset_v: "-0.1"