silverstone

Solar Enthusiast

- Joined

- May 3, 2022

- Messages

- 1,059

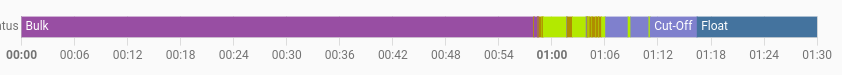

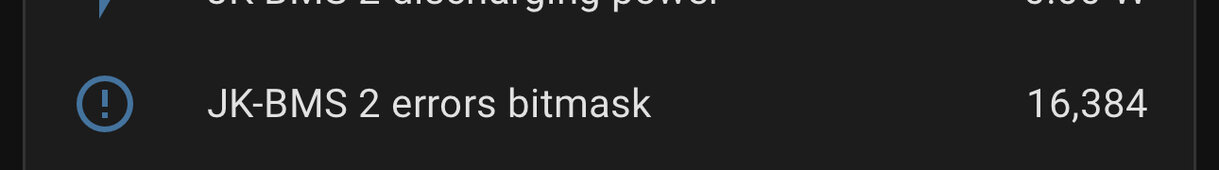

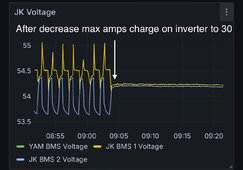

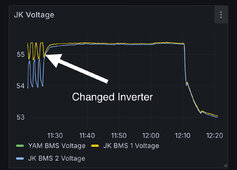

Careful with that though (think about the inrush Current if they reconnect if the Voltage difference is too high, you will need to inhibit that IMHO).For the moment, the BMS in error are decombined, the load values will be adapted for the number of BMS remaining but if you are in Bulk phase you remain in Bulk, I could change that in the future, to think about.

BMS in error protect themselves by deactivating their charge and discharge switch.

E.g. only allow reconnect on if abs(U_BMS_Healthy - U_BMS_Faulty) < 0.5VDC or something like that ...

(or more complex if you only turn on the Charge OR the Discharge Switch depending on the Situation of course)