So I'm looking to generate enough solar power to run two newer freezers and a newer fridge that are in my garage. I ran the Kill a watt on the first freezer and came out with 650 watt power consumption in 24 hours. Until I measure the other two I'm going to guess that 3 kilowatts of power a day should run all three.

Solar array.

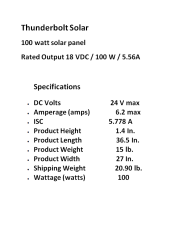

At this time, all I have actually purchased is 10 Harbor Freight 100 watt solar panels. Their rated power is 18 V DC @ 5.56 amps. Maximum is 24 V DC @ 6.2 amps.

Looking at a series parallel configuration of the 10 panels I figure 90 V DC @ 11 amps best case. I get a solid 6 hours of sun at my location so again best case is 6000 watts per day. Probably around 5000 watts or less would be more realistic. Maybe.

Supposedly the solar array wattage at the rated output would be around 1000 watts but at the max rating it could be almost 1500 watts. Or higher if I understand how the cooler weather affects the panels.

Charge controller.

I've been looking at the 60 amp EPEVER Tracer AN series MPPT charge controller. At the 24V setting it is rated at 1500 watts on the input. I'm not sure if that is enough under the cooler weather conditions but I have read that you can over panel this controller. Since I'm just getting started I'm really not trying to push any sort of limits at this time.

Battery.

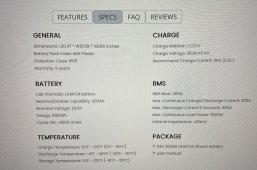

I was looking at the LiTime 24V 200Ah LiFePO4 Lithium Battery or possibly stepping up to the 24V 230Ah version if needed. To be truthful I'm not sure if my panels will charge the 200Ah let alone the 230Ah. Since this is the most expensive part I don't mind spending a little more if needed.

So if I may humbly ask the board a few questions, please keep in mind that I figure I know just about enough to get myself in trouble.

At 1500 watts input on the charge controller, is it large enough to handle my solar array output when the weather cools off?

Will my array supply enough wattage to fully charge the 200Ah battery?

Do you think if I get the batteries fully charged they can supply enough power for the 2 freezers and the fridge?

How big of a Pure Sine Wave Converter to power the 3 appliances?

A bit more background.

I want to mount the system in the garage close to the appliances.

I looked at the All In One Systems but figured I would learn more with a separate component system and it would be easier to repair if something went wrong.

I bought the 10 Thunderbolt 100 watt solar panels over an 8 month period when on sale and have less than $1000 dollars invested.

I have had 46 years of dependable power from TVA but that all ended last year as we were subjected to rolling blackouts for the first time.

I am open to any and all suggestions.

If you have a better way to meet the goal please feel free to let me know your ideas.

As always, I am grateful to anyone who provides feedback on my system

Thanks in advance.

Solar array.

At this time, all I have actually purchased is 10 Harbor Freight 100 watt solar panels. Their rated power is 18 V DC @ 5.56 amps. Maximum is 24 V DC @ 6.2 amps.

Looking at a series parallel configuration of the 10 panels I figure 90 V DC @ 11 amps best case. I get a solid 6 hours of sun at my location so again best case is 6000 watts per day. Probably around 5000 watts or less would be more realistic. Maybe.

Supposedly the solar array wattage at the rated output would be around 1000 watts but at the max rating it could be almost 1500 watts. Or higher if I understand how the cooler weather affects the panels.

Charge controller.

I've been looking at the 60 amp EPEVER Tracer AN series MPPT charge controller. At the 24V setting it is rated at 1500 watts on the input. I'm not sure if that is enough under the cooler weather conditions but I have read that you can over panel this controller. Since I'm just getting started I'm really not trying to push any sort of limits at this time.

Battery.

I was looking at the LiTime 24V 200Ah LiFePO4 Lithium Battery or possibly stepping up to the 24V 230Ah version if needed. To be truthful I'm not sure if my panels will charge the 200Ah let alone the 230Ah. Since this is the most expensive part I don't mind spending a little more if needed.

So if I may humbly ask the board a few questions, please keep in mind that I figure I know just about enough to get myself in trouble.

At 1500 watts input on the charge controller, is it large enough to handle my solar array output when the weather cools off?

Will my array supply enough wattage to fully charge the 200Ah battery?

Do you think if I get the batteries fully charged they can supply enough power for the 2 freezers and the fridge?

How big of a Pure Sine Wave Converter to power the 3 appliances?

A bit more background.

I want to mount the system in the garage close to the appliances.

I looked at the All In One Systems but figured I would learn more with a separate component system and it would be easier to repair if something went wrong.

I bought the 10 Thunderbolt 100 watt solar panels over an 8 month period when on sale and have less than $1000 dollars invested.

I have had 46 years of dependable power from TVA but that all ended last year as we were subjected to rolling blackouts for the first time.

I am open to any and all suggestions.

If you have a better way to meet the goal please feel free to let me know your ideas.

As always, I am grateful to anyone who provides feedback on my system

Thanks in advance.