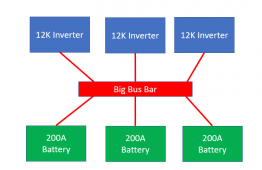

So, I'm building fairly big, 43kW panels, 3x12kW Deye SG04LP3 inverters and 3x48v@280Ah Mason DIY kits

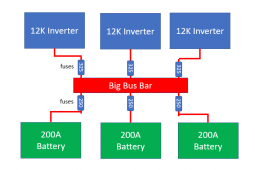

For charging and discharging the batteries I am aiming for less than 0.5c on regular use, but I could have situations where a higher load is required and thus I need to run a little less than 200A from each battery(BMS max 200A), giving me around 600A.

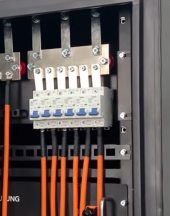

So I need busbars that can handle a load like that.

For 3 inverters and 3 batteries, I need at least 6 connection points, cables from the battery come standard with 50mm2 lugs and I plan on running the same from the inverters.

Does this exist in the market? If so, can you point me to it, because I haven't been able to find it.

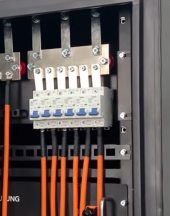

I saw something clever on a Seplos installation video and I was hoping to have something similar, just with its own enclosure as I not building a rack.

Preferably something that's purchasable within the EU.

For charging and discharging the batteries I am aiming for less than 0.5c on regular use, but I could have situations where a higher load is required and thus I need to run a little less than 200A from each battery(BMS max 200A), giving me around 600A.

So I need busbars that can handle a load like that.

For 3 inverters and 3 batteries, I need at least 6 connection points, cables from the battery come standard with 50mm2 lugs and I plan on running the same from the inverters.

Does this exist in the market? If so, can you point me to it, because I haven't been able to find it.

I saw something clever on a Seplos installation video and I was hoping to have something similar, just with its own enclosure as I not building a rack.

Preferably something that's purchasable within the EU.

Last edited: