pointless_cog

New Member

Hi,

First time poster, so apologies if this is in the wrong spot!

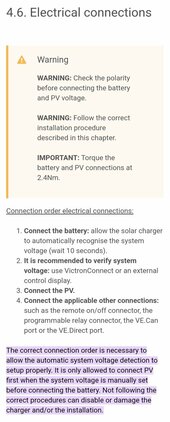

We are developing a portable solar charging system, which has a Victron SmartSolar 75/15 between the panels and a battery system I have no control over (long story). Anyway, the MPPT will be housed inside a clear lidded, polycarb box, along with the required breakers, fuses, etc. Unfortunately, and again outside of my control, both the solar input connectors and the battery system outlet connectors are going to be MC4.

Whilst I will be labelling these extremely clearly, the users of this system could plug the solar in the output side and the battery in the input side of the MPPT.

I'm wondering if anyone can give me some guidance on what might happen if this swap occurred?

First time poster, so apologies if this is in the wrong spot!

We are developing a portable solar charging system, which has a Victron SmartSolar 75/15 between the panels and a battery system I have no control over (long story). Anyway, the MPPT will be housed inside a clear lidded, polycarb box, along with the required breakers, fuses, etc. Unfortunately, and again outside of my control, both the solar input connectors and the battery system outlet connectors are going to be MC4.

Whilst I will be labelling these extremely clearly, the users of this system could plug the solar in the output side and the battery in the input side of the MPPT.

I'm wondering if anyone can give me some guidance on what might happen if this swap occurred?