whereitsat42

New Member

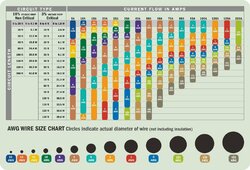

Hi all, need some help: my panels are installed on ground mounts between 45-65 feet from my junction box and, like a moron, I made the classic mistake of not doubling the length of my cable runs from the panels to the box when sizing my wires, and need to upgrade from the 10 awg wires I have now. I have four inputs on my junction box, each connected to three 320w/24v panels in series (so roughly 13.3 amps/72v max apiece), and according to my consultation of THE CHART, and accepting a moderate but not horrible voltage drop, 6 awg seems to be the way to go. Only problem is I can't seem to find 50-65 foot 6 awg cables anywhere with the mc4 connectors already on them. I can get just the copper wire, but can't find 6 awg connectors for sale either. I'm assuming the 45-65 feet, while not ideal, also isn't radically uncommon, so does anyone know somewhere reliable where I could find this stuff reasonably easy? As an added bonus, have I already fried anything running 10 awg cables, or has the charge just dropped off to practically nothing using that wire?