joesmith123

New Member

Error code 09

Details before it went out: It would lose connection to the 48 volt battery system, the display read 38 volts but when I check with volt meter, it says 48 volt

took off the cover, I do have multimeter, how do I check what is the problem?

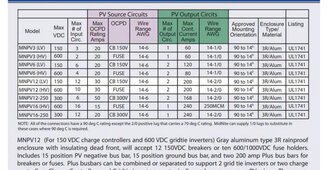

Here's a new main board if needed

Let me know which fuses to check before installing a new board

Could it be the part that accepts the 48 volt system, and feeds it to the main board? That component would be where the + and - terminals connect on the bottom

thanks

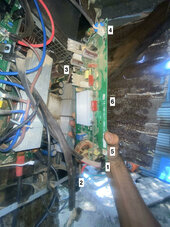

Took it apart

took off the PV input board

Up close of the connectors from small board that accepts the 48 volt connection, going to the main board, those are the two rails that go to the main board, they look fried

1st plan before changing board: unbolt those connectors, hit it with wire wheel and polish it, then see if she reads proper voltage

Main connectors on the main board, fried, took awhile to get the bolts off, burnt everything

One of the most important connectors, the metal is very low quality

Plan: hit the area with wire wheel on dremel, polish it, put the 48 volt leads directly onto the main board, then melt solder onto that area since there is no way to screw the nuts back onto those bolts

Details before it went out: It would lose connection to the 48 volt battery system, the display read 38 volts but when I check with volt meter, it says 48 volt

took off the cover, I do have multimeter, how do I check what is the problem?

Here's a new main board if needed

Let me know which fuses to check before installing a new board

Could it be the part that accepts the 48 volt system, and feeds it to the main board? That component would be where the + and - terminals connect on the bottom

thanks

Took it apart

took off the PV input board

Up close of the connectors from small board that accepts the 48 volt connection, going to the main board, those are the two rails that go to the main board, they look fried

1st plan before changing board: unbolt those connectors, hit it with wire wheel and polish it, then see if she reads proper voltage

Main connectors on the main board, fried, took awhile to get the bolts off, burnt everything

One of the most important connectors, the metal is very low quality

Plan: hit the area with wire wheel on dremel, polish it, put the 48 volt leads directly onto the main board, then melt solder onto that area since there is no way to screw the nuts back onto those bolts

Last edited: