Daddy Tanuki

Solar Wizard

Been talking about this for over a year now, its time to get started,

So originally this idea was formulated as a way to use up excess production as my panels and batteries are all specc'd for winter time with low solar output, and then it morphed into why not heat the house, or at least the underside of the house to prevent pipe freezing. This then mixed in my brain with my desires to build a waste oil burner for heating the large portions of the shop and in the end the decision was to make a waste oil boiler.

so through the entire year, I make enough excess to heat water for general use... bathing etc. and i think after crunching numbers until my brain was jello, that in the months of April/May (early spring) and maybe late September early October (late fall) the excess solar production makes enough that I can even keep the house warm at night.

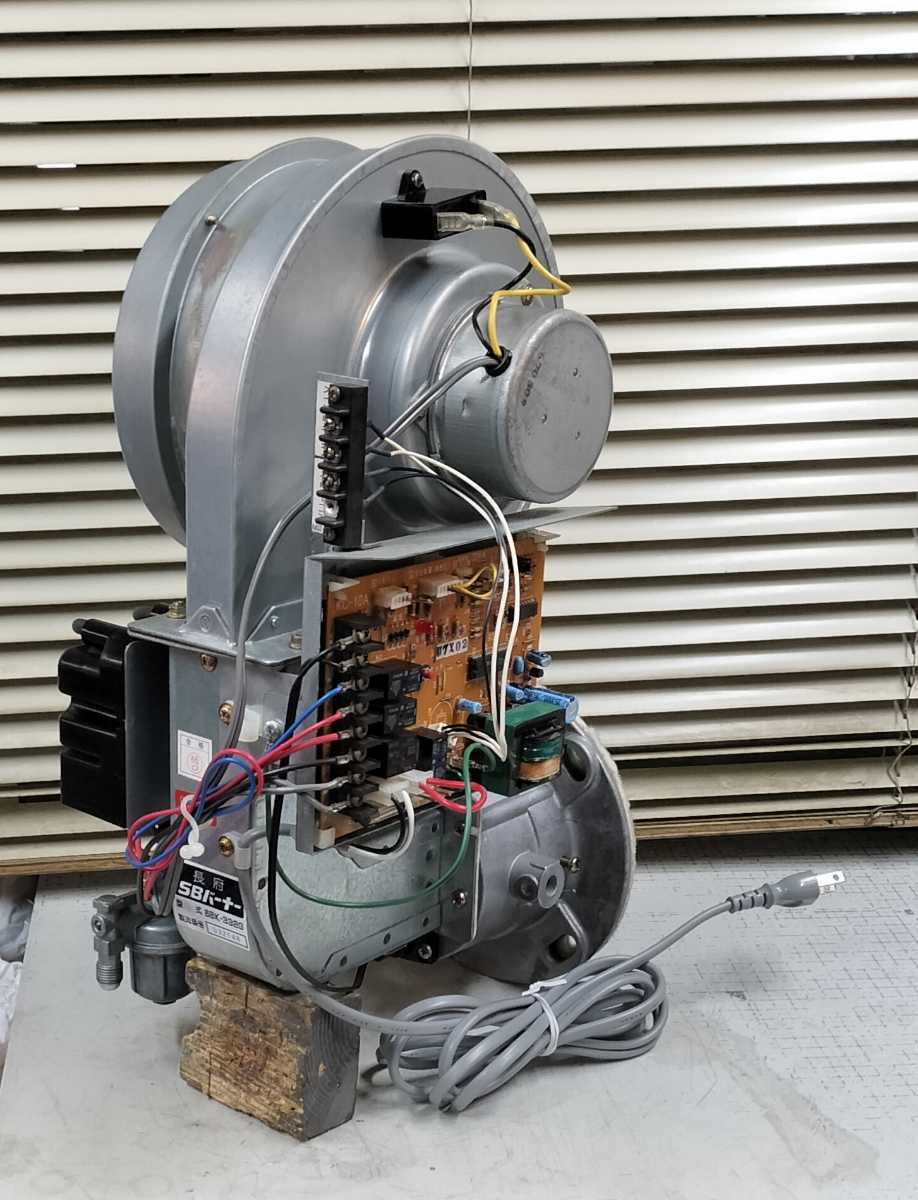

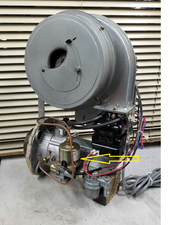

the months between October-April are another story entirely... and that's where the waste oil boiler will come into play. currently working with a person in the states who specializes in waster oil burners and between the two of us we are working on using a honeywell aquastat to turn the waste oil burner on and off, along with some other circuits to make it pretty much hands free other than filling the waste oil tank (and all the prep needed for that, centerfuge, filter pre heat etc.).

this will cover the tank, heat exchanger, electrical heating elements and everything except the controls for the waste oil boiler.

when I can i iwll list the prices paid converted to USD at the time of purchase along with the exchange rate.

warning, picture heavy:

2023 fall

1700 liter insulated milk tank side view ¥80,000/130 = $615.00 Local purchase.

1700 liter tank front view

2024 mid May Stainless 1/2" pipe in coils for heat ex-changer ¥120,000/160 = $800.00 China/alibaba.

Mid May Stainless steel sheet cut to strip and making heat exchanger coil supports

late June 2024 start excavating

July 4th-8th 2 cubic meters of gravel to prevent frost heave in winter gravel ¥12,000 $78 USD at 155/$

Concrete pad will be 2 meters x 4 meters and 8" +- 1" thick. single 10mm rebar with 5mm rebar mesh. final area to be enclosed, 2/4 stick build with single slant roof, insulated and extra space will hold future washer and dryer hence the drain pipe at the end of the pad for the washer.

wore the F out... 27-28 °c but humidity is off the charts.

conrete poured next week after the forms are removed I will lay the blocks for the building. concrete with pump truck is ¥110,000 or $709.00 @155/$ and then an extra ¥10,000 to a neighbor who is good at floating concrete, (or at least better than I am) .

![IMG_2333[1].JPG IMG_2333[1].JPG](https://diysolarforum.com/data/attachments/228/228422-70695cac503ba5796d7bc877c36cbc1e.jpg)

to be continued:

So originally this idea was formulated as a way to use up excess production as my panels and batteries are all specc'd for winter time with low solar output, and then it morphed into why not heat the house, or at least the underside of the house to prevent pipe freezing. This then mixed in my brain with my desires to build a waste oil burner for heating the large portions of the shop and in the end the decision was to make a waste oil boiler.

so through the entire year, I make enough excess to heat water for general use... bathing etc. and i think after crunching numbers until my brain was jello, that in the months of April/May (early spring) and maybe late September early October (late fall) the excess solar production makes enough that I can even keep the house warm at night.

the months between October-April are another story entirely... and that's where the waste oil boiler will come into play. currently working with a person in the states who specializes in waster oil burners and between the two of us we are working on using a honeywell aquastat to turn the waste oil burner on and off, along with some other circuits to make it pretty much hands free other than filling the waste oil tank (and all the prep needed for that, centerfuge, filter pre heat etc.).

this will cover the tank, heat exchanger, electrical heating elements and everything except the controls for the waste oil boiler.

when I can i iwll list the prices paid converted to USD at the time of purchase along with the exchange rate.

warning, picture heavy:

2023 fall

1700 liter insulated milk tank side view ¥80,000/130 = $615.00 Local purchase.

1700 liter tank front view

2024 mid May Stainless 1/2" pipe in coils for heat ex-changer ¥120,000/160 = $800.00 China/alibaba.

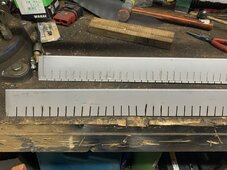

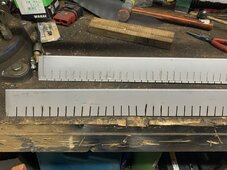

Mid May Stainless steel sheet cut to strip and making heat exchanger coil supports

late June 2024 start excavating

July 4th-8th 2 cubic meters of gravel to prevent frost heave in winter gravel ¥12,000 $78 USD at 155/$

Concrete pad will be 2 meters x 4 meters and 8" +- 1" thick. single 10mm rebar with 5mm rebar mesh. final area to be enclosed, 2/4 stick build with single slant roof, insulated and extra space will hold future washer and dryer hence the drain pipe at the end of the pad for the washer.

wore the F out... 27-28 °c but humidity is off the charts.

conrete poured next week after the forms are removed I will lay the blocks for the building. concrete with pump truck is ¥110,000 or $709.00 @155/$ and then an extra ¥10,000 to a neighbor who is good at floating concrete, (or at least better than I am) .

![IMG_2333[1].JPG IMG_2333[1].JPG](https://diysolarforum.com/data/attachments/228/228422-70695cac503ba5796d7bc877c36cbc1e.jpg)

to be continued:

Last edited: