42OhmsPA

What's in a title?

I'm probably over thinking this...

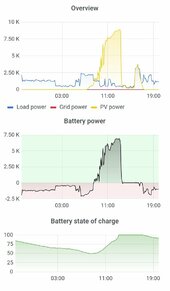

I currently have an oil fired water heater and excess solar.

If I were to add a small 120V heater before my current heater could I get the small heater to circulate and heat the oil fired tank?

It wouldn't work if I just plumbed the new hot out to the old cold in and reduced the temp, correct? I would need another loop to let it circulate?

Anyone have a visual?

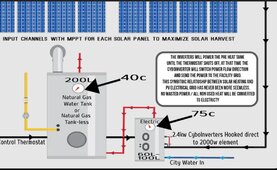

I'm thinking something like this on a timer or a voltage based relay.

I currently have an oil fired water heater and excess solar.

If I were to add a small 120V heater before my current heater could I get the small heater to circulate and heat the oil fired tank?

It wouldn't work if I just plumbed the new hot out to the old cold in and reduced the temp, correct? I would need another loop to let it circulate?

Anyone have a visual?

I'm thinking something like this on a timer or a voltage based relay.

Bosch 4 Gal. Mini-Tank Electric Water Heater ES 4 - The Home Depot

The Bosch 4 Gal. Electric Water Heater has a 4 Gal. mini-tank that fits under your sink to provide hot water right where you need it. The heater plugs right into a 120-Volt outlet and has a lightweight,

www.homedepot.com