wait, what?painting

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Campervan 24V 280AH LiFePO4 3 x 370W solar panels

- Thread starter beton

- Start date

Have you gone down the road of figuring out how you'll attach the awning to the roof and what you'll use for slide mechanisms?

I'm not sure the specs/limits of the promaster roof but the sprinter 170 HR is 330 pounds limit. If I do 4-5 panels I'm looking at about a 100 pounds left for mounting hardware.

I'm planning to use aluminum extrusion such as that on 8020.net with either their linear rails, or long drawer slides, or something else (still looking around). In an ideal world it would also be able to tilt (the entire sub frame, so that all panels would be in same alignment), and even better would be if it could be motorized (both the tilting and the awning) because it's pretty high up there... Then maybe I could wire an ignition disconnect or at least a blaring warning if the car starts while the panels are out I might be asking for too much given I only have 100 pounds to work with

I might be asking for too much given I only have 100 pounds to work with

It's obviously absolutely crucial that the panels don't fly off when in motion, so I'll probably add some sort of manual/physical lockdown of some sort and some retaining wires.

If I'm parked in Idaho for a semi permanent stay and get a foot of snow that'll be like 1200 pounds of additional weight, so there might need to be support columns.

An option that crosses my mind but probably isn't that smart is just a hinge, and flipping the panels out 180°. That seems sturdy, and might be okay for normal driving if I used bifacial panels. I'm not quite certain what the breakdown of "awning out" vs "in" time will be, I suppose if there isn't room to extend there probably won't be much in terms of solar potential either.

Anyway, would love to hear what you've come up with in terms of ideas or hardware for all that.

I'm not sure the specs/limits of the promaster roof but the sprinter 170 HR is 330 pounds limit. If I do 4-5 panels I'm looking at about a 100 pounds left for mounting hardware.

I'm planning to use aluminum extrusion such as that on 8020.net with either their linear rails, or long drawer slides, or something else (still looking around). In an ideal world it would also be able to tilt (the entire sub frame, so that all panels would be in same alignment), and even better would be if it could be motorized (both the tilting and the awning) because it's pretty high up there... Then maybe I could wire an ignition disconnect or at least a blaring warning if the car starts while the panels are out

It's obviously absolutely crucial that the panels don't fly off when in motion, so I'll probably add some sort of manual/physical lockdown of some sort and some retaining wires.

If I'm parked in Idaho for a semi permanent stay and get a foot of snow that'll be like 1200 pounds of additional weight, so there might need to be support columns.

An option that crosses my mind but probably isn't that smart is just a hinge, and flipping the panels out 180°. That seems sturdy, and might be okay for normal driving if I used bifacial panels. I'm not quite certain what the breakdown of "awning out" vs "in" time will be, I suppose if there isn't room to extend there probably won't be much in terms of solar potential either.

Anyway, would love to hear what you've come up with in terms of ideas or hardware for all that.

At this stage the details have not been worked out other than concept. I like the idea of 8020 for the van build, but find it hard to justify the cost. Now that I know my key components, I am redesigning the internal, then I will do a rough takeoff of the internal 8020 and price it. I will have to be 100% correct in the takeoff and order of the 8020 so that I only have one transport charge. I am in Perth Western Australia and the delivery charges are criminal.

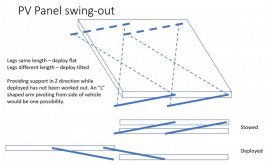

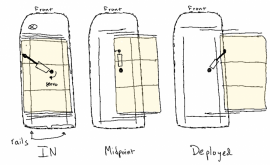

The promaster has roof rack lugs. It has a 150kg limit. Thus the frame has to be aluminum. 8020 would allow me to play around and develop the mechanisms. The frame has to be solidly made. I am looking at the top three panels in a frame approx 8 inches above the roof. One side will be hinged and two actuators to tilt. (The tilt is only an option at present as I have to see that there is benefit here in Australia in tilting). The load is only needed when the weather is hot which is summer and the sun is pretty well overhead anyway. The top three panels are really stock standard.

The slide out two panels are different. I went with two because the only practical method of slide out is drawer slides. The panels will need to slide out further than the top panels to avoid shading. This will need a strip of flashing as the panels will double as an awning. Thus I need to use 48 inch drawer slides. There is a big step in price to 72 inch slides and they will not hide the lower panels as well as being wider than the the roof rack tracks.

We fortunately do not have the snow loads to contend with but we do have wind loads. Especially in the outback where willy-willys (mini tornadoes) can spring up very quickly. Thus we will must likely need 2 slides per panel (2 sets).

The drawer slide will need to be (a) high capacity and (b) stainless steel. This latter requirement is a concern due to rusting from inferior quality and dissimilar materials. I think that a 8020 solution may be too bulky. The slide out will be on actuators.

My work load is still heavy at this stage, but I will break out the 8020 manual.

The promaster has roof rack lugs. It has a 150kg limit. Thus the frame has to be aluminum. 8020 would allow me to play around and develop the mechanisms. The frame has to be solidly made. I am looking at the top three panels in a frame approx 8 inches above the roof. One side will be hinged and two actuators to tilt. (The tilt is only an option at present as I have to see that there is benefit here in Australia in tilting). The load is only needed when the weather is hot which is summer and the sun is pretty well overhead anyway. The top three panels are really stock standard.

The slide out two panels are different. I went with two because the only practical method of slide out is drawer slides. The panels will need to slide out further than the top panels to avoid shading. This will need a strip of flashing as the panels will double as an awning. Thus I need to use 48 inch drawer slides. There is a big step in price to 72 inch slides and they will not hide the lower panels as well as being wider than the the roof rack tracks.

We fortunately do not have the snow loads to contend with but we do have wind loads. Especially in the outback where willy-willys (mini tornadoes) can spring up very quickly. Thus we will must likely need 2 slides per panel (2 sets).

The drawer slide will need to be (a) high capacity and (b) stainless steel. This latter requirement is a concern due to rusting from inferior quality and dissimilar materials. I think that a 8020 solution may be too bulky. The slide out will be on actuators.

My work load is still heavy at this stage, but I will break out the 8020 manual.

I don't think this has been posted in this thread yet. If it has, my apologies for reposting it. I thought his design was quite good.

Frequently Asked Questions – Solar Slide Edition – Everlanders

This video goes into more details about how the slide mechanism was created.

Frequently Asked Questions – Solar Slide Edition – Everlanders

This video goes into more details about how the slide mechanism was created.

Thanks for posting HRTKD.

This is one of six videos that I have seen addressing the slide out panels. It also is the one I like the most. The area of concern is the SS drawer slides. The panels that I will be using are 44 inches wide. Thus I will need 48 inch slides. These will need to be north of 200lbs capacity. They will be in the weather all the time. My concern is the quality of the SS and the subsequent rusting.

I would use a linear actuator. The aluminum sections are readily available. I can get all sections prepared and I have a nephew who would weld it together. Cost a slab of booze.

This is one of six videos that I have seen addressing the slide out panels. It also is the one I like the most. The area of concern is the SS drawer slides. The panels that I will be using are 44 inches wide. Thus I will need 48 inch slides. These will need to be north of 200lbs capacity. They will be in the weather all the time. My concern is the quality of the SS and the subsequent rusting.

I would use a linear actuator. The aluminum sections are readily available. I can get all sections prepared and I have a nephew who would weld it together. Cost a slab of booze.

where did you find those? I have a similar project, just need to slide one panel...I did find these. They come in a range of diameters. I have not given any thought to how they would work as we would need two stages to be deployed fully with strength.

View attachment 30264

For the drawer slider I am also concern about freezing temperature, dust and dirt, I like the one above more.....

I think if you search "linear motion shaft" or "linear rod" you may find some.where did you find those? I have a similar project, just need to slide one panel...

For the drawer slider I am also concern about freezing temperature, dust and dirt, I like the one above more.....

I'm currently stuck on the notion of drawer slides and trying to think of easier ways to add automation.

One idea is a gas-strut/shock (or two) connected to a servo that controls the deployment.

It seems based on easily available sizes (about at the limit of available length) it would be possible to deploy a 60" awning.

@alvise also, I've been looking at these and they seem available:

and they have a nice online tool for doing some sizing calculations:

drylin-linear-guides-expert.igus.tools

drylin-linear-guides-expert.igus.tools

(And seem responsive, regional sales manager called me today, I'll report back once I play around with some numbers)

and they have a nice online tool for doing some sizing calculations:

drylin® linear guides expert

(And seem responsive, regional sales manager called me today, I'll report back once I play around with some numbers)

https://fr.aliexpress.com/item/32957706632.html I have not looked for a site in English.

I ended up ordering a Victron SmartSolar 100/50 and a 150/35. The latter because it will better accommodate the full wattage of 2 panels and will also work with 2 in series.

5 PowerXT 400's should be arriving tomorrow. That is, assuming the delivery truck doesn't get stuck before it reaches my house like it did on the last 2 attempts...I'll definitely be checking them closely.

I plan to run 2 panels lengthwise for the next few months while I work out the details on the awning.

5 PowerXT 400's should be arriving tomorrow. That is, assuming the delivery truck doesn't get stuck before it reaches my house like it did on the last 2 attempts...I'll definitely be checking them closely.

I plan to run 2 panels lengthwise for the next few months while I work out the details on the awning.

I put the cart before the horse. I worked out an ideal van layout based on the promaster (Ducato here) long wheel based extended. I saw a good few driving around and said "I pick up a second hand one". Scarcer than rockinghorse shyte. Thus I have to do a major rethink to seeing what sort of van I can get and do a quick think as whether my wants can be accommodated and jump into the fire. This may extend to a box truck (far easier to get.

Similar threads

- Replies

- 5

- Views

- 440

- Replies

- 26

- Views

- 767

- Replies

- 2

- Views

- 146