Bill Taylor

New Member

- Joined

- Apr 30, 2020

- Messages

- 75

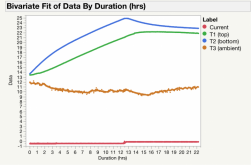

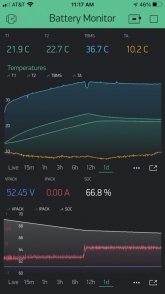

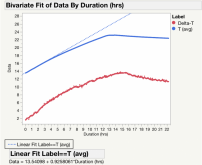

OK, so I got the first round of testing done. This is a quick update, when I get the data collected I will present it in a more organized fashion. I used a chest freezer at 0°F. I repeated the test using three different 100ah non-heated lifepo4 batteries, to get an average. The results were nearly identical, so for the sake of time I will just use one going forward. For consistency, all batteries were charged completely at room temperature @ .2C and placed in the freezer for 12 hours before the discharge test began. I have a few preliminary thoughts:

1. The batteries warmed up *much* faster than I thought they would at .25C discharge.

2. I assumed the charge inhibit function would allow a very small charge in, even at freezing temperatures, this was not the case. I had to move the battery into the refrigerator overnight and warm it up to 38°F. I charged the battery at .25C, it warmed up much less than it did when it was discharged in the freezer.

3. I will use my IR camera next time to determine if the heat is coming from the cells or the BMS, and attach those images to the final report.

4. I also tried identical testing with a brand new AGM battery. I was expecting a severe reduction in power... not true. It did produce less, but considering it was at 0°F, it held up surprisingly well.

5. This is a lot more time-consuming than I originally thought. I do not have any data logging equipment, I'm doing it the old-fashioned way with a notebook and pen. It will take a few weeks or more to complete the testing. The internet is full of theory and assumptions. I'm looking forward to getting some real-world results together to serve as a reference. Stay tuned.

1. The batteries warmed up *much* faster than I thought they would at .25C discharge.

2. I assumed the charge inhibit function would allow a very small charge in, even at freezing temperatures, this was not the case. I had to move the battery into the refrigerator overnight and warm it up to 38°F. I charged the battery at .25C, it warmed up much less than it did when it was discharged in the freezer.

3. I will use my IR camera next time to determine if the heat is coming from the cells or the BMS, and attach those images to the final report.

4. I also tried identical testing with a brand new AGM battery. I was expecting a severe reduction in power... not true. It did produce less, but considering it was at 0°F, it held up surprisingly well.

5. This is a lot more time-consuming than I originally thought. I do not have any data logging equipment, I'm doing it the old-fashioned way with a notebook and pen. It will take a few weeks or more to complete the testing. The internet is full of theory and assumptions. I'm looking forward to getting some real-world results together to serve as a reference. Stay tuned.