How about laser welding? Is it possible that caused the cell damage? While BB may have inspected 100,000 cells, those were most probably fresh from the supplier. They surely did not open up every fully manufactured box to see if cells got damaged by the manufacturing process. I think they may end up needing to do that. For now it would be advisable to up their inspection game, way up. The chance that this was the luck of the draw at 10,000 to 1 odds is just way too remote.6.7 Don’t solder the battery directly.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Leaking Electrolyte from Bigbattery Powerblock

- Thread starter Will Prowse

- Start date

DerpsyDoodler

Solar Addict

- Joined

- Jan 10, 2021

- Messages

- 2,247

The statistics have to land somewhere, though I am inclined to agree. Just trying to remain unbiased in preference of more information.How about laser welding? Is it possible that caused the cell damage? While BB may have inspected 100,000 cells, those were most probably fresh from the supplier. They surely did not open up every fully manufactured box to see if cells got damaged by the manufacturing process. I think they may end up needing to do that. For now it would be advisable to up their inspection game, way up. The chance that this was the luck of the draw at 10,000 to 1 odds is just way too remote.

Joe BoyKey

Watts, Watts, more Watts

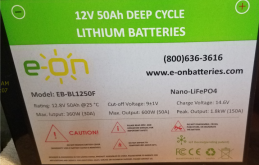

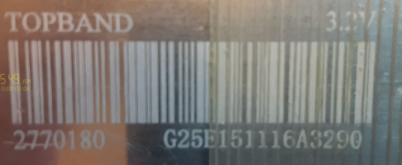

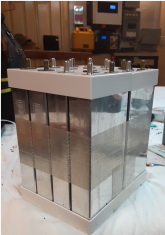

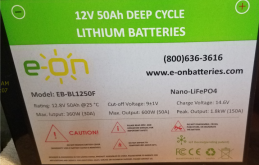

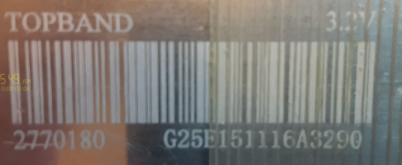

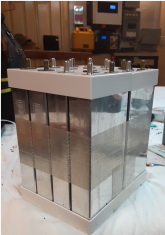

Ok, have 18 of these 4p4s (51.2v 200sh) 2 extra, each battery has 8 TopBand 3.2v 25ah cells 2p4s, the same as the recent POPULAR Navitas cells.

1. Cells are laying on their side when the battery is upright.

2. There is no plastic insulator between cells, does have gap made by upper/lower plastic holders.

3. Plastic spacer is in place, voltage can be read between terminal and case, but disappears when shorted - 0 ma draw.

Fyi - These batteries are from felled solar project and set in a barn in south Texas, date on each box was 4yrs old

2 out of 18 had a problem, 1 no bluetooth the other reads 48ah on the app, both work fine - they are spare.

1. Cells are laying on their side when the battery is upright.

2. There is no plastic insulator between cells, does have gap made by upper/lower plastic holders.

3. Plastic spacer is in place, voltage can be read between terminal and case, but disappears when shorted - 0 ma draw.

Fyi - These batteries are from felled solar project and set in a barn in south Texas, date on each box was 4yrs old

2 out of 18 had a problem, 1 no bluetooth the other reads 48ah on the app, both work fine - they are spare.

Last edited:

You guys are yolo so I don't have to be. Thanks much for that data point. How did you know it wouldn't explode?I think it made a spark that had then ignited the now vaporized electrolyte.

Of course it does, because it's shorted. Then you're just measuring the resistance of the aluminum. Don't mean to disparage your post, it's a great one, I just couldn't let that one govoltage can be read between terminal and case, but disappears when shorted

WillI told them today that it confused me that my pack didn't leak for a month. I didn't touch it. Then it started leaking out of the blue. That's why I took the packs off my site. I don't trust them. I agree with you guys.

That looks like it's in a trailer- is that right? Did you move it during the month, or did it sit the whole time?

There is has been good points brought up for loading, but the loading changed when it's a static bundle vs a dynamic shock. So if the vehicle was moved, it's possible that enough bumps were hit to exceed the pressure load locally. This is why I asked about cushioning earlier in the thread- the idea would be mounting the batteries vertically in a plastic box (milk crate- I'm not creative, and are happy to copy good ideas), and then mount that on a pad over the firm surface.

I doubt it's as simple as that. Maybe it's a variety of coulombic explosion. That is, it's the charge release that raises the temperature to the ignition point. Which would raise the question, why doesn't it ignite immediately? And what happens if the spear is non-conductive, does the smoking even happen? I am guessing, it doesn't. Only one thing is certain: needs further research.Your comment about a spark sounds correct.

No, did not drive trailer. Moved battery carefully inside, and it sat for one night. That's it.Will

That looks like it's in a trailer- is that right? Did you move it during the month, or did it sit the whole time?

There is has been good points brought up for loading, but the loading changed when it's a static bundle vs a dynamic shock. So if the vehicle was moved, it's possible that enough bumps were hit to exceed the pressure load locally. This is why I asked about cushioning earlier in the thread- the idea would be mounting the batteries vertically in a plastic box (milk crate- I'm not creative, and are happy to copy good ideas), and then mount that on a pad over the firm surface.

InterestingOk, have 18 of these 4p4s (51.2v 200sh) 2 extra, each battery has 8 TopBand 3.2v 25ah cells 2p4s, the same as the recent POPULAR Navitas cells.

1. Cells are laying on their side when the battery is upright.

2. There is no plastic insulator between cells, does have gap made by upper/lower plastic holders.

3. Plastic spacer is in place, voltage can be read between terminal and case, but disappears when shorted - 0 ma draw.

Fyi - These batteries are from felled solar project and set in a barn in south Texas, date on each box was 4yrs old

2 out of 18 had a problem, 1 no bluetooth the other reads 48ah on the app, both work fine - they are spare.

View attachment 37628 View attachment 37629

View attachment 37630

Ok, interesting. Makes how this plays out even more interesting.No, did not drive trailer. Moved battery carefully inside, and it sat for one night. That's it.

Although if the cause was shock loading, that would be very helpful information, too.

I know there is no intention, especially to send them to a YouTuber that will put together and show avideo to 10's of thousands of potential customers. I just honestly don't trust their numbers. It does not take into account the number of cells already sold and or shipped. Its obviously a design, manufacturing and construction issue. I just really feel these numbers are much higher.Just got an update. They found 11 bad cells out of 100,000. Seems like a lot of people had to sort cells this morning.

View attachment 37428

DerpsyDoodler

Solar Addict

- Joined

- Jan 10, 2021

- Messages

- 2,247

Their response is too quick. They didn’t take the time to thoroughly investigate. Perhaps it’s multiple problems, not just one. Given their track record..I do not trust a 2hr response unless this was already a known issue. Has anyone seen a recall or announcement for the safety of their customers? I would expect that of a known issue.I know there is no intention, especially to send them to a YouTuber that will put together and show avideo to 10's of thousands of potential customers. I just honestly don't trust their numbers. It does not take into account the number of cells already sold and or shipped. Its obviously a design, manufacturing and construction issue. I just really feel these numbers are much higher.

I did some reading on the hydrolysis of the PF6 ions present in the electrolyte (it disassociates from the lithium in solution). There really isn't much discussion of this issue outside of fires though.

Hydrolysis of PF6– ions occurs only in the presence of water in a medium which is not too acidic or basic (pH between 1 and 12) However, the kinetics of this hydrolysis are not favorable. The reaction is slow and the quantities of released hydrofluoric acid will not be very important.[2]

www.prevor.com

www.prevor.com

[2] The analytical and descriptive inorganic chemistry of the hydrolysis of hexafluoropnictate ions PnF6-, M.Ponikvar, B. Zemva, J.F. Liebman, J. Fluor. Chem. 2003, 123, 217-220.

It sounds like HF production from the electrolyte, even when spilled, is minor. The exception is if water is in direct contact with the electrolyte. Even then its not a fast process at room temperature.

The lesson here, is don't use water to clean up unless the area is very well ventilated. The exception to this is skin contact, flush with water immediately and for several minutes.

For those using the cells on a boat, just make sure that leaking electrolyte can get into the bilge. A plastic drip pan with sufficient capacity will work.

Hydrolysis of PF6– ions occurs only in the presence of water in a medium which is not too acidic or basic (pH between 1 and 12) However, the kinetics of this hydrolysis are not favorable. The reaction is slow and the quantities of released hydrofluoric acid will not be very important.[2]

Lithium-ion batteries: why and when do they pose a risk of chemical exposure for people? - PREVOR

In recent years, there has been an increase in the use of motorised personal mobility devices (MPMDs) equipped with a non-combustion engine such as scooters, bicycles, unicycles, hoverboards and similar devices. Like more and more electric vehicles, most MPMDs contain lithium-ion batteries...

[2] The analytical and descriptive inorganic chemistry of the hydrolysis of hexafluoropnictate ions PnF6-, M.Ponikvar, B. Zemva, J.F. Liebman, J. Fluor. Chem. 2003, 123, 217-220.

It sounds like HF production from the electrolyte, even when spilled, is minor. The exception is if water is in direct contact with the electrolyte. Even then its not a fast process at room temperature.

The lesson here, is don't use water to clean up unless the area is very well ventilated. The exception to this is skin contact, flush with water immediately and for several minutes.

For those using the cells on a boat, just make sure that leaking electrolyte can get into the bilge. A plastic drip pan with sufficient capacity will work.

Poverty Pony

New Member

- Joined

- Feb 19, 2021

- Messages

- 25

maybe they're thinking $899 for a 100Ah battery that doesn't leak isn't so bad after all? That's what I'm thinking... I had been trying to get BigBattery on the phone to order one of their systems, but considering I can't get through to sales (and no answer to my emails) I'm imaging that getting actual customer service when your pack leaks in 5 years is going to be an even bigger challenge.hrm... I wonder what battleborn is thinking about all this

Alkaline

Solar Wizard

woa they probably did because its 1050 now.

I bet they are now trying to decide if they have to do a recall. The expense of which could put them out of business. https://www.cpsc.gov/Recalls/2002/c...-flashlights-and-batteries-sold-in-kids-mealsTheir response is too quick. They didn’t take the time to thoroughly investigate. Perhaps it’s multiple problems, not just one. Given their track record..I do not trust a 2hr response unless this was already a known issue. Has anyone seen a recall or announcement for the safety of their customers? I would expect that of a known issue.

DerpsyDoodler

Solar Addict

- Joined

- Jan 10, 2021

- Messages

- 2,247

Either that or quietly investigating/muddling over a way to cover up that they knew of this potential issue and didnt bother issuing a warning or safety notice? If that is the case (pun anyone?), good riddance. Coverups like that can get people hurt or killed.I bet they are now trying to decide if they have to do a recall. The expense of which could put them out of business. https://www.cpsc.gov/Recalls/2002/c...-flashlights-and-batteries-sold-in-kids-meals

Edit: Im not trying to sound like I’ve made a decision on big battery one way or the other, but now is not the time for them to be quiet. Now is the time to be as open and transparent as possible, and to rectify any mistakes if there were any.

Last edited:

Bob B

Emperor Of Solar

- Joined

- Sep 21, 2019

- Messages

- 8,735

This is the only post I remember on this forum about cells leaking electrolyte .... I didn't do a full search, so there could be more.

Based on the leakage problem being rare .... and most people are mounting the cells vertically in their DIY packs .... I would speculate that horizonal orientation is not a good idea.

I did find this response from EVE to @Gazoo who had asked them questions about their recommendation for a compression fixture. The note at the end about the leak being internal is by Gazoo ..... but, it seems to me that if the port on the top of the cell is below the level of the electrolyte as it will be when the cell is horizontal, that the chance of an external leak is greatly increased.

Following is from that post ..... I asked EVE about compression as follows:

Could you please explain the following quoted from your 280ah cell specification:

"At 25±2℃,the battery under 300kgf fixture : charging the cell with charge current 1.0C(A) and constant voltage 3.65V,0.05C cut off,rest for 30min,discharge to 2.5V cut off with the current of 1.0C(A),rest for 30min,and then start the next cycle,end with the capacity decrease to 80% of the initial capacity.The number of cycles is defined as the cycle life of the battery."

Why is a fixture required?

Is it to prevent expansion of the cells for longer cycle life?

If the cells are mounted in a fixture so they can not expand will that work?

And this was EVE's reply:

Hello,

Your understanding is right. During the charge & discharge process of battery, the cell will “breath” like people does- swell & shrink effect.

The function of fixture, we use the clamp, is to prevent the over-swelling effect, which is likely to cause electrolyte leak furthermore.

Thus the fixture will guarantee longer life.

Thank you & Best Regards

NOTE: When they refer to electrolyte leak they are referring to the innards of the cell. It is not external.

Based on the leakage problem being rare .... and most people are mounting the cells vertically in their DIY packs .... I would speculate that horizonal orientation is not a good idea.

I did find this response from EVE to @Gazoo who had asked them questions about their recommendation for a compression fixture. The note at the end about the leak being internal is by Gazoo ..... but, it seems to me that if the port on the top of the cell is below the level of the electrolyte as it will be when the cell is horizontal, that the chance of an external leak is greatly increased.

Following is from that post ..... I asked EVE about compression as follows:

Could you please explain the following quoted from your 280ah cell specification:

"At 25±2℃,the battery under 300kgf fixture : charging the cell with charge current 1.0C(A) and constant voltage 3.65V,0.05C cut off,rest for 30min,discharge to 2.5V cut off with the current of 1.0C(A),rest for 30min,and then start the next cycle,end with the capacity decrease to 80% of the initial capacity.The number of cycles is defined as the cycle life of the battery."

Why is a fixture required?

Is it to prevent expansion of the cells for longer cycle life?

If the cells are mounted in a fixture so they can not expand will that work?

And this was EVE's reply:

Hello,

Your understanding is right. During the charge & discharge process of battery, the cell will “breath” like people does- swell & shrink effect.

The function of fixture, we use the clamp, is to prevent the over-swelling effect, which is likely to cause electrolyte leak furthermore.

Thus the fixture will guarantee longer life.

Thank you & Best Regards

NOTE: When they refer to electrolyte leak they are referring to the innards of the cell. It is not external.

Similar threads

- Replies

- 14

- Views

- 666

- Replies

- 4

- Views

- 3K