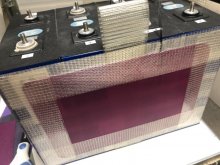

Probably a low probability problem, but all it takes is one good knock and road forces/dynamics are hard to anticipate. Maybe a couple wood or plastic strips just a bit thicker than the BMS taped to that side of the box or cells. If there wasn't that metal strip across the top, you could count on the battery box to flex/give on impact at bit, but I think you could end up with all the force of those cells hitting that thin metal strip with the BMS as the "meat" in the sandwich.With my current layout of foam, I have a continuous band on 3 sides and some smaller blocks on the BMS side, so the only direction the cells want to move is toward the BMS (unfortunately), but it’s tough to tell if it’s really a problem or not.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

4S 272/280ah enclosure suggestion

- Thread starter uberpixel

- Start date

I had actually already taped an extra layer of cutting board plastic to this side of the cells as an added buffer. Just didn’t mention in my previous build notes. I appreciate that you’ve identified one of the potential failure points that I was concerned about. Confirms my thinking...Probably a low probability problem, but all it takes is one good knock and road forces/dynamics are hard to anticipate. Maybe a couple wood or plastic strips just a bit thicker than the BMS taped to that side of the box or cells. If there wasn't that metal strip across the top, you could count on the battery box to flex/give on impact at bit, but I think you could end up with all the force of those cells hitting that thin metal strip with the BMS as the "meat" in the sandwich.

-uberpixel

Mike Jordan

Solar Enthusiast

- Joined

- Jun 15, 2020

- Messages

- 414

Genius design! Well done all the way around

This is what I used [link]You mentioned thin cutting board between the cells, do you know the actual thickness?

Was at wally world tonight they had some white 8.5 x 11 cutting boards guesstimate 1/8" for .88 cents i bought all 5. Still need more.

They are quite thin at only 0.02” or 0.5mm.

-uberpixel

Nice work. I guess it never hurts to ask! I'm definitely impressed with the case. VERY sturdy and well built. Maybe I'll reach out to them and see if they'll give me a deal on some lock cores for the latches...I happened to contact this company (seahorse) and they offered me a 15% discount code and said share it with the group. So if you place an order for this use code FIFTEEN.

-uberpixel

Just an update on the ICECO VL45 cooler test with this battery. So far it's been running for 14 days on one charge. I have the temp set to 36F, the compressor speed on the 'MIN' setting, and the battery protection on 'LOW'. The test started with the cooler sitting in my living room at room temp and it ran for a while to get a case of beer down to 36F.Dude this is awesome and love the ICECO I have been using their fridges for good while. I have one in my car at all times freezer and fridge. So I would like to hear some test how long that battery pack powers that fridge? I ran mine with no charge over a week. that is with one side 0F and other at around 34F.

So far it uses around 10Ah of juice every day. Starting voltage was 13.8V, current voltage is 13.11V, and my BMS thinks I have 37% capacity remaining (based on voltage FWIW). At this rate it should go another 10 days or so... By then I'll definitely need another case of beer.

My intention was to just plug in the cooler to do an easy capacity test of the battery since I don't have my inverter wired up yet. I should have my RV electrical done soon so I can do a more "real world" capacity test with a higher load and get a few cycles under my belt.

-uberpixel

This just convinces me its a good idea to pitch this ****ed up SLA technology. Im lucky if my national luna runs 24 hrs on 2 6v 225ah golf cart batteries.Just an update on the ICECO VL45 cooler test with this battery. So far it's been running for 14 days on one charge. I have the temp set to 36F, the compressor speed on the 'MIN' setting, and the battery protection on 'LOW'. The test started with the cooler sitting in my living room at room temp and it ran for a while to get a case of beer down to 36F.

So far it uses around 10Ah of juice every day. Starting voltage was 13.8V, current voltage is 13.11V, and my BMS thinks I have 37% capacity remaining (based on voltage FWIW). At this rate it should go another 10 days or so... By then I'll definitely need another case of beer.

My intention was to just plug in the cooler to do an easy capacity test of the battery since I don't have my inverter wired up yet. I should have my RV electrical done soon so I can do a more "real world" capacity test with a higher load and get a few cycles under my belt.

-uberpixel

Dont know if youre still following your thread, but on that aluminum angle that the bms mounts to- can that be made in 1 1/4 x 3/16? Just because I have some laying around. I downloaded the template and figured i could just move it over 1/4".

Sorry - just saw this... Might be a bit too late, but you should be able to make that work. As you said, might need to shift the pattern over a bit so you don't squeeze the cells with the additional angle thickness. It will fit either way, but might just get a bit tight - and the PDF might need a little massaging to work.Dont know if youre still following your thread, but on that aluminum angle that the bms mounts to- can that be made in 1 1/4 x 3/16? Just because I have some laying around. I downloaded the template and figured i could just move it over 1/4".

-uberpixel

I noticed your original plan included a resettable breaker, i couldnt figure out a good mounting option for that. What I did just order was a blue sea mini on off switch that should fit between the output terminalsSorry - just saw this... Might be a bit too late, but you should be able to make that work. As you said, might need to shift the pattern over a bit so you don't squeeze the cells with the additional angle thickness. It will fit either way, but might just get a bit tight - and the PDF might need a little massaging to work.

-uberpixel

and a buss mbrt fuse holder

that can mount to the switch. Im going to shallow surface mount the switch. Together they were about ,$65 + tax. I really like the idea of switching the battery after its connected. The fuse holder is cool, however replacement fuses are $15. Ouch. I prolly should have just bolted an anl or mega fuse in there.

Similar threads

- Replies

- 2

- Views

- 147

- Replies

- 10

- Views

- 329

- Replies

- 10

- Views

- 431

- Replies

- 29

- Views

- 1K